When it comes to the 14 elements of PSM, you need all of them to run a successful process safety management program. Imagine you have strong employee participation but outdated training. While your workers may be willing to participate, they may not have the knowledge or skills needed to spot hazards or prevent incidents. Review each of the elements below to make sure your program covers the entirety of OSHA’s requirements.

PSM Compliance Audit Guide

Download this guide to review your program’s compliance with each line of the OSHA PSM standard.

What are the 14 Process Safety Management Elements?

According to OSHA’s website, the goal of the PSM standard is to:

“[Prevent or minimize] the consequences of catastrophic releases of toxic, reactive, flammable, or explosive chemicals…[that] may result in toxic, fire or explosion hazards.”

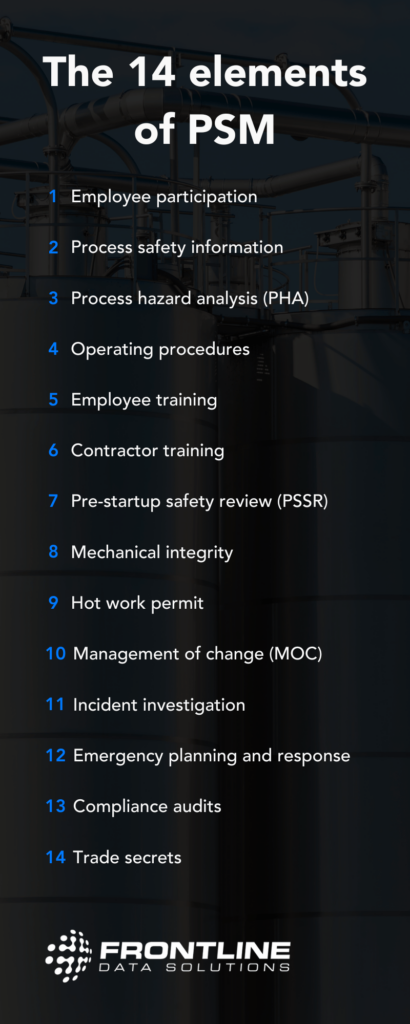

The 14 elements of PSM are:

- Employee Participation

- Process Safety Information

- Process Hazard Analysis (PHA)

- Operating Procedures

- Employee Training

- Contractor Training

- Pre-Startup Safety Review (PSSR)

- Mechanical Integrity

- Hot Work Permit

- Management of Change (MOC)

- Incident Investigation

- Emergency Planning and Response

- Compliance Audits

- Trade Secrets

Let’s define each of these elements below.

Employee Participation

You must encourage (and sometimes require) employees to participate in PSM-related initiatives such as training, safety culture surveys, feedback, and reward programs.

Process Safety Information

Process safety information includes documentation outlining the specific safety protocols that you have in place. The type of data that process safety information includes would be anything related to hazardous technology, equipment, chemicals, etc., within the operation.

Process Hazard Analysis (PHA)

A process hazard analysis is an assessment of the potential hazards within your operation. You must complete PHAs for all your processes to ensure that preventative safety measures are in place.

Operating Procedures

Every business that falls under PSM compliance must have written operating procedures. These procedures must provide clear instructions to workers performing the related task. They should also be easily accessible to all employees.

Employee Training

Your PSM program must ensure that employees receive the required safety and process-specific training. You must document all training either manually or with a learning management system to ensure that training records are accurate.

Contractor Training

Training contractors is one of the hardest elements of PSM compliance to implement, due to the difficulty of managing third-party workers. You must ensure that all contractor workers receive appropriate training for the hazardous chemicals that they’ll work with.

Pre-Startup Safety Review

Whenever you open a new facility, remodel a facility, or introduce a new piece of equipment, you must complete a pre-startup-safety review. You can learn more about PSSR requirements here and use this free PSSR checklist to get started.

Mechanical Integrity

Under PSM, your critical process equipment must be designed and installed correctly. This applies to storage tanks and vessels, pumps, piping systems, valves, emergency shutdown systems, and controls. In order to comply with OSHA mechanical integrity standards, your equipment must be fabricated for the process it’s intended for.

Our mechanical integrity overview explains this element of PSM in much more detail and our PSM Mechanical Integrity Form should give you an idea of what to do at your site for this requirement.

Hot Work Permit

Employees must have a hot work permit in order to perform hot work activities conducted on or near a covered process. Here’s a permit template you can use for your operation.

Management of Change (MOC)

Management of change (MOC) refers to the standard process that everyone must follow when implementing process, equipment, or personnel changes. Implementing an MOC program properly can be very difficult without some sort of MOC tracking system or standardized workflow.

Incident Investigation

Whenever there is a near miss or safety incident, you must investigate it. During this investigation, you should identify the root cause(s), brainstorm corrective actions, and track EHS action items to completion.

Emergency Planning and Response

Every site, regardless of whether it falls under the PSM standard, should have comprehensive emergency response plans in place. In addition to documenting these protocols, you should train your employees how to act quickly in a variety of emergency situations.

Compliance Audits

At least once every three years, you must certify that your operation is compliant with the PSM standard. Check out these process safety indicators to monitor for a better idea of how to conduct an audit.

Trade Secrets

The last element of PSM is trade secrets which refers to any classified documentation within your organization that pertains to PSM. Under OSHA’s regulation, you must provide any PSM-related information, regardless of whether it contains trade secrets, to employees and their representatives. OSHA does, however, state that you can require non-disclosure agreements to anyone who receives trade secrets as a result of PSM compliance.

Why Do I Need a PSM Program?

OSHA introduced the PSM standard to help companies prevent hazardous chemical safety incidents. If you work in chemical manufacturing or other PSM-regulated environments, then a PSM program will help you not only meet the standard’s requirements but also improve overall operational performance.

Implementing all 14 process safety management elements helps you build a cohesive incident prevention strategy. And many of these elements have a direct positive impact on other areas of EHS performance. Therefore, with these measures in place, your workforce is better equipped to identify and control hazards proactively.

Under PSM compliance, workers receive frequent updates when process, equipment, or personnel changes occur. And efficiency is possible when everyone is on the same page about what to do and why to do it.

What are the Benefits of PSM?

Here are top 5 benefits of PSM compliance if you implement the framework correctly:

- Avoid incident costs by minimizing hazardous releases, injuries, and down time.

- Decrease response times to incidents or near misses.

- Reduce the impact of incidents before they cause major issues.

- Analyze the root cause of an incident or near miss.

- Plan operational changes with a minimal impact on daily operations.

Implementing a PSM program at a company for the first time is often overwhelming. This is especially true if you’ve never worked in PSM compliance and are just trying to figure out what’s required. It’s not a task you can complete in a few days or even weeks.

If you’re feeling overwhelmed, start by reviewing what (if anything) you have in place for each element on its own. You might find that you’re already meeting certain requirements. This will give you more space to focus on the process safety management elements that you haven’t implemented yet.