PSSR Checklist

Resources >Template Library > PSSR Checklist

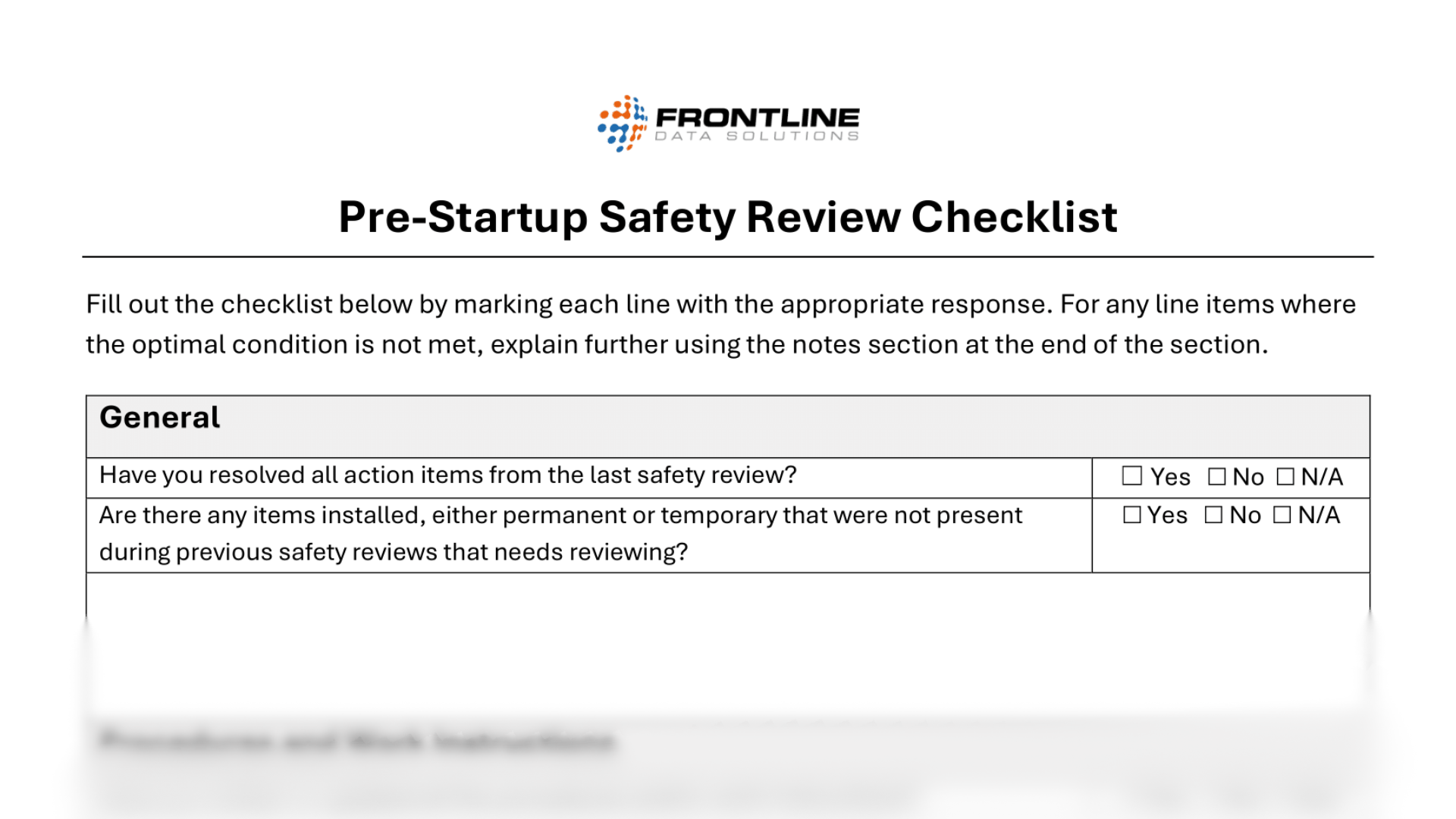

Download this free PSSR Checklist from Frontline Data Solutions to document your all your team’s pre-startup safety review.

Get a Free Copy Instantly

What is a Pre-Startup Safety Review (PSSR)?

A pre-startup safety review is a formal check completed before a new or modified process goes into operation. It ensures that all safety, environmental, and operational requirements are addressed before startup. The PSSR is a critical component of process safety management (PSM) and is required under OSHA’s 29 CFR 1910.119 for covered facilities.

The purpose of a PSSR is to confirm:

- Equipment is properly installed and inspected

- Safety systems and controls function correctly

- Procedures and documentation are accurate

- Personnel receive training on the new or modified process

- Hazards resulting from the change are identified and controlled

Conducting a PSSR will help you prevent startup incidents, reduce compliance risks, and ensure that everyone aligns on the requirements for a safe launch.

What Is a PSSR Checklist?

A PSSR checklist is a standardized document for verifying that your team completes all necessary safety reviews, procedures, and requirements before starting up a new or modified process. It’s a required element under OSHA’s PSM standard for covered facilities and a best practice for any site managing high-risk operations.

When Should You Use a Checklist?

You should use a PSSR checklist any time you make a change that could impact safety, operations, or compliance. Our clients do PSSRs for all sorts of changes, including when they:

- Install or modify equipment

- Change process parameters or materials

- Update control systems

- Relocate assets

- Reconfigure workspaces

Even if a change seems minor, it can introduce new hazards. A pre-startup safety review ensures that safeguards, procedures, and training are in place beforehand.

Why a PSSR Checklist Matters

Skipping the pre-startup safety review can cause equipment failures, unexpected downtime, environmental releases, injuries or fatalities, regulatory citations, and more. Having a final checklist as part of your startup process reduces the chance of any one of these. That’s because this step holds your team accountable to fully documenting the work they’ve done leading up to the change.

What To Include in a PSSR Checklist

Your PSSR checklist should reflect your facility’s specific risks, but most include these core elements:

- Change Description: What changed? Include reference numbers or related documentation.

- Process Safety Information: Have you updated all necessary documentation? (e.g., P&IDs)

- Equipment Readiness: Is the equipment installed, inspected, and ready for operation?

- Instrumentation and Controls: Have you tested safety systems, alarms, and interlocks?

- Hazard Identification: Have you reviewed and mitigated potential risks?

- Operating Procedures: Are your written procedures complete and up to date?

- Training: Have operators and affected personnel received training on the change?

- Emergency Planning: Have you reviewed and updated emergency procedures if needed?

- Approvals and Sign-Offs: Have all responsible parties signed off on the readiness for startup?

- Open Action Items: Are there any remaining issues?

Example of How PSSR Prevent Accidents

Imagine you install a new pump as part of an upgrade. Without a PSSR checklist:

- The operator may not know the startup procedure changed.

- Maintenance might skip testing the interlock.

- The emergency shutdown instructions might still reflect the old setup.

A checklist forces each responsible team to verify their part of the process is ready before an incident happens. If you’re developing or refining your process safety workflows, download our checklist to ensure your next startup is safe, compliant, and complete.

More Templates to Discover

Found this template helpful? You might like some of these, too: