Process Safety Management Software

Strengthen your EHS program with Frontline’s process safety management software. Centralize PSM activities, automate compliance workflows, and keep your workforce aligned on critical safety procedures.

The Frontline Solution

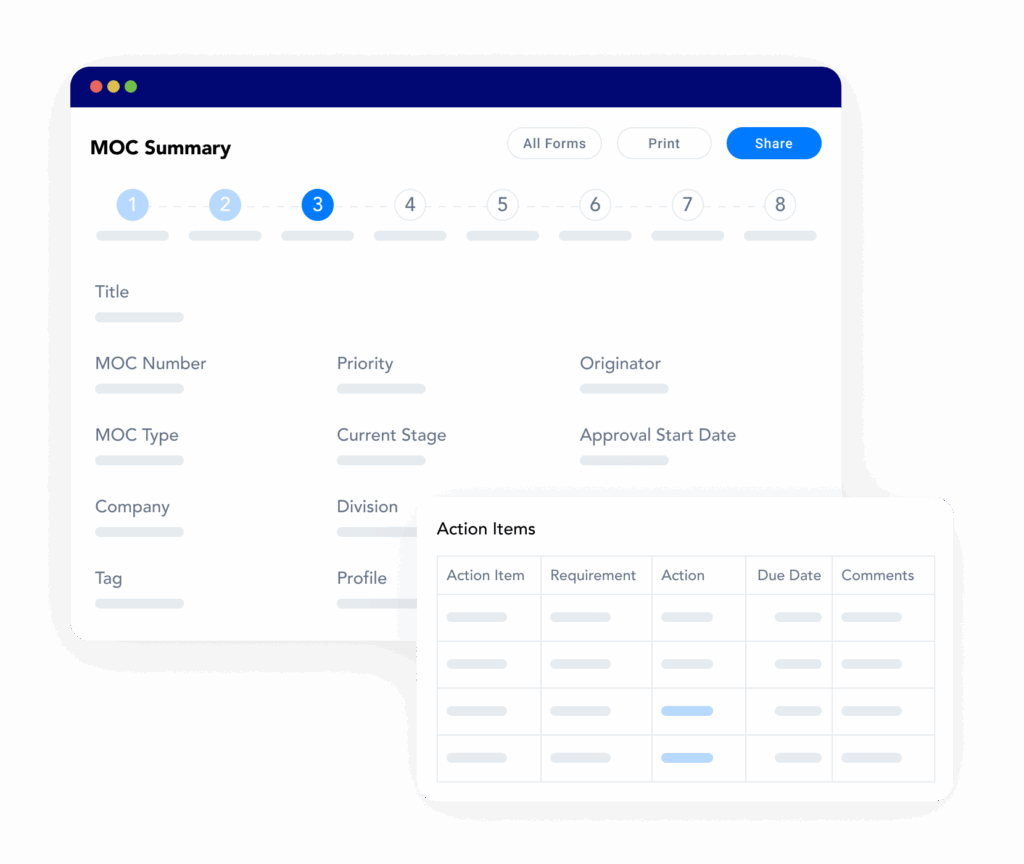

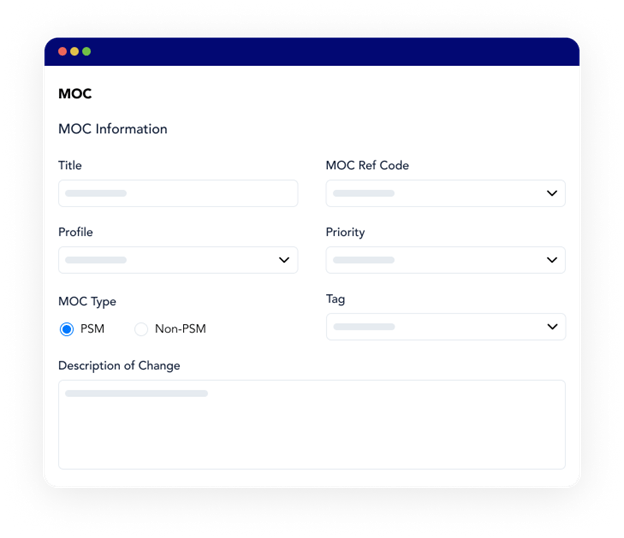

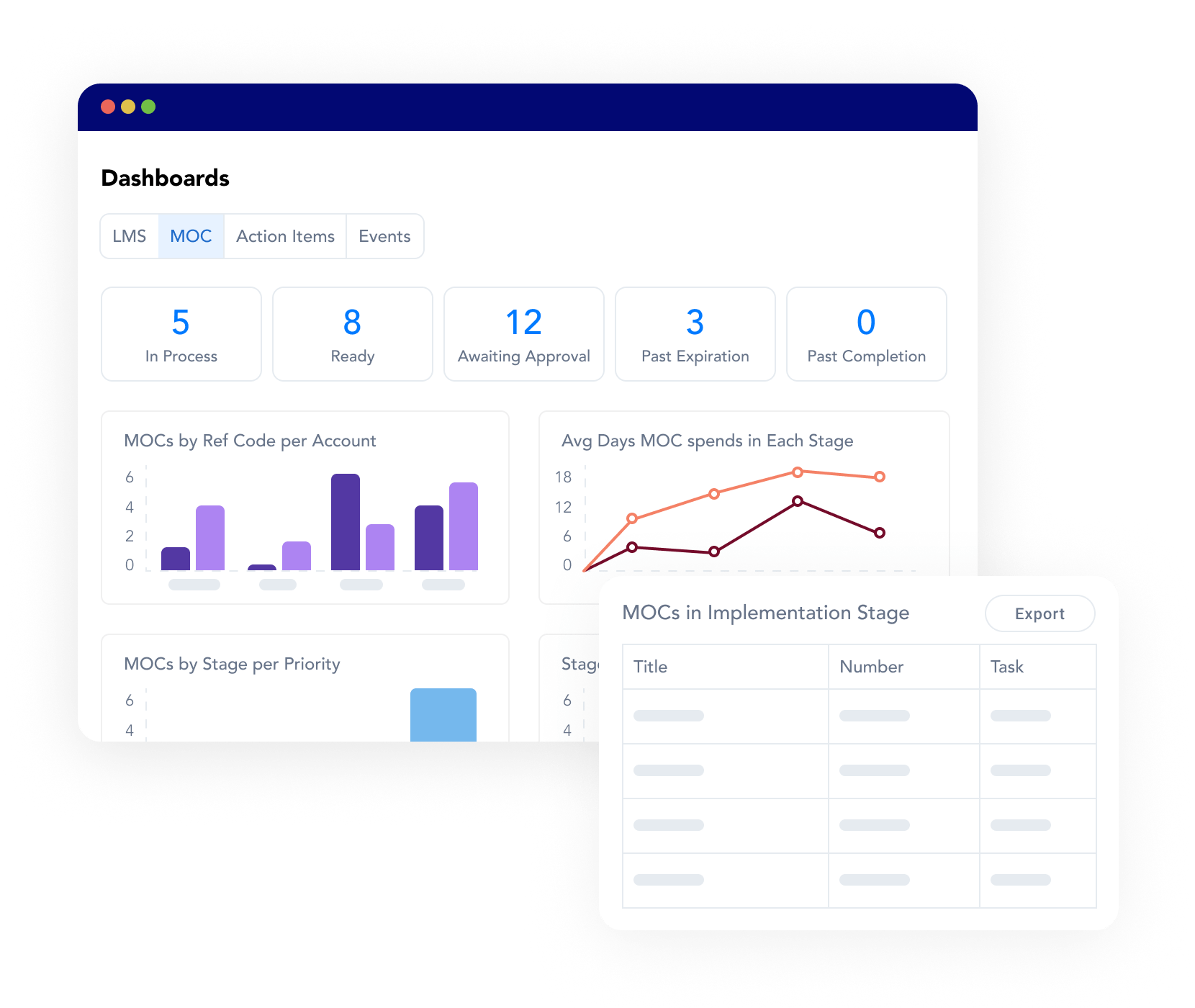

Frontline offers the right tool for every stage of safety and compliance management. For this use case, Frontline MOC helps organizations meet OSHA 1910.119 requirements and manage process safety changes, documentation, and training with ease. With structured workflows, automated approvals, and complete audit trails, you can ensure control and document the elements of PSM.

Improve Oversight

Gain full visibility into all process safety activities with automated workflows and centralized documentation.

Maintain Compliance

Standardize procedures and approvals to stay aligned with OSHA’s 14 elements of process safety management.

Reduce Risk

Identify and address potential hazards proactively with built-in review steps and traceable risk assessments.

Digitize and Simplify PSM Programs

Eliminate the manual burden of tracking process safety activities across spreadsheets and paper records. Frontline MOC gives you a single, digital platform to manage the people, processes, and equipment changes that affect facility safety.

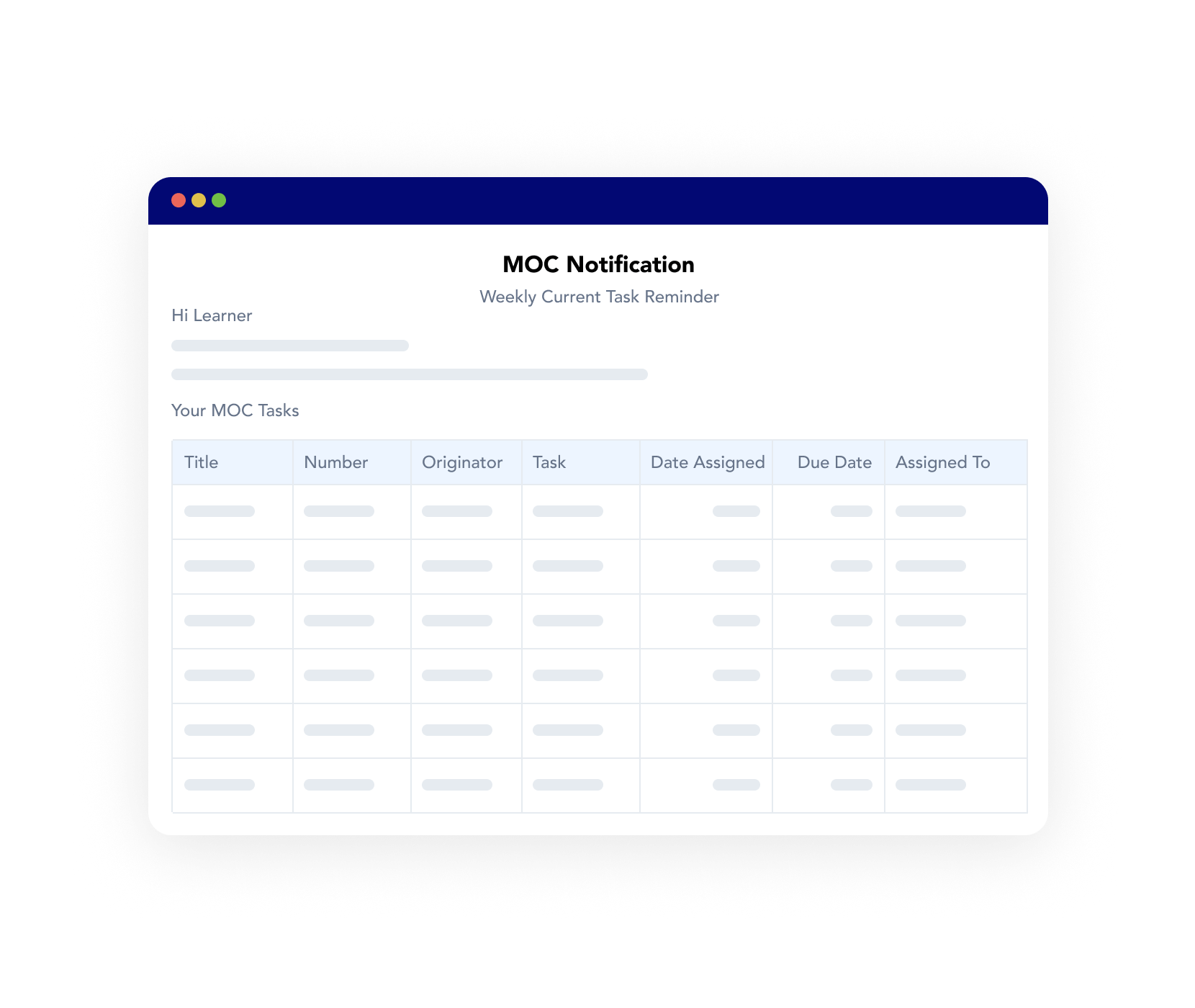

Connect People, Procedures, and Compliance

Keep your team informed and trained before implementing any new processes. With Frontline MOC, you can ensure that changes don’t go into effect until you’ve completed a full review.

PSM Compliance Audit Guide

Download this guide to review your program’s compliance with each line of the OSHA PSM standard.

Prepare for Audits with Confidence

Generate clear reports that show how you reviewed, approved, and communicated each change. Frontline MOC keeps your process safety program ready for regulatory inspections at all times.

EHS Software Pricing Calculator

Explore EHS software costs with our free pricing calculator and get an instant quote!

Frequently Asked Questions

Book a Demo

Book a personalized demo with our team to learn how EHS software from Frontline Data Solutions can help you simplify safety, reduce risk, and protect frontline workers.