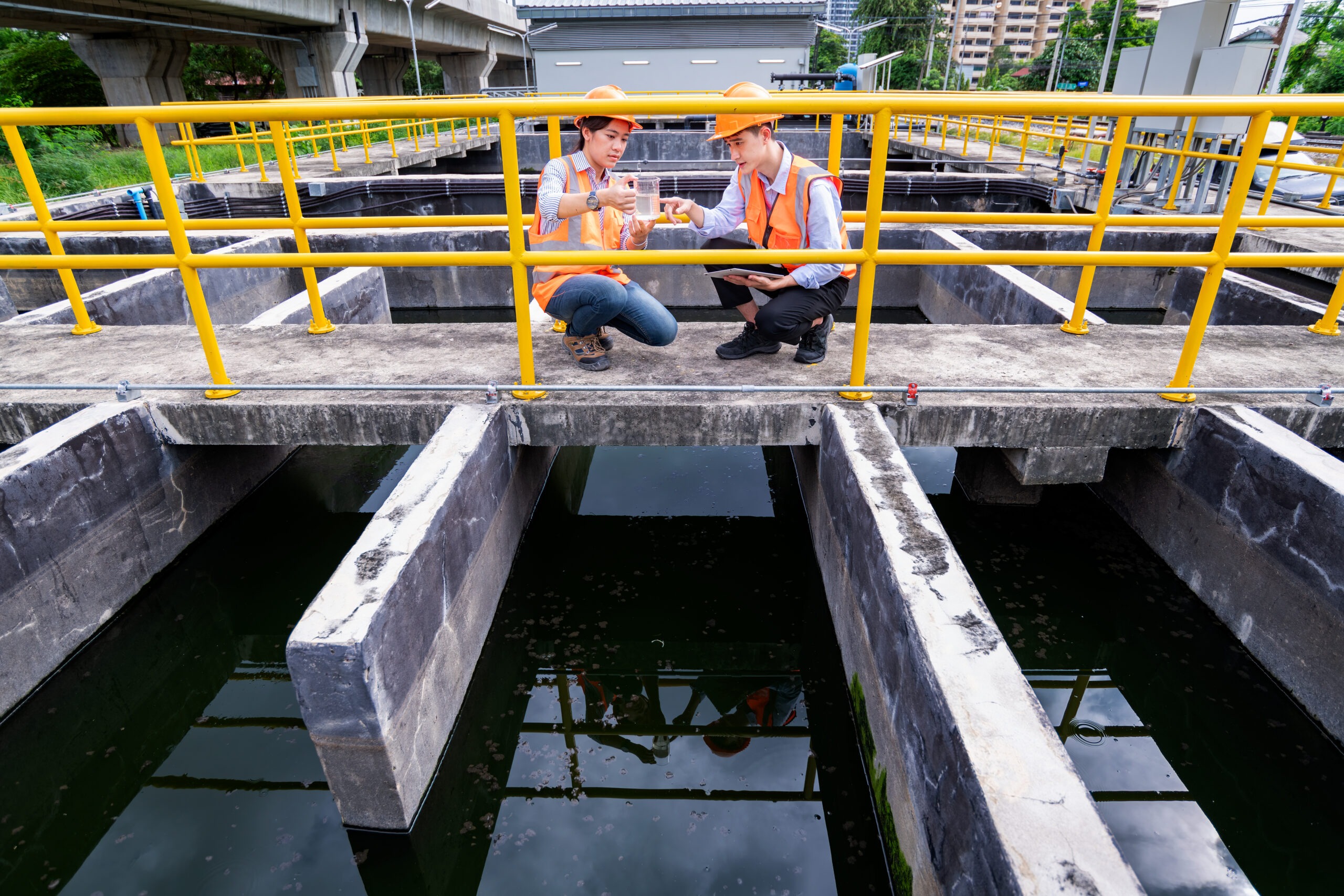

When using wastewater treatment chemicals in the U.S., you must understand the regulations that apply to the substances at your site. To ensure compliance, manage these chemicals properly throughout their lifecycle.

Additionally, national reporting requirements apply to many of these substances. You must identify and report specific chemicals annually through documents such as the Tier II report, Form R, and the Toxic Release Inventory (TRI). These reports must disclose which chemicals you store and the quantities kept onsite.

Making changes to chemical processes or wastewater treatment

Additional coordination with your local municipality or the wastewater treatment plant (where you discharge your treated water to) is also essential. When considering chemicals for wastewater treatment, ensure they align with your operating permit before making any changes. You also need to make sure that changes don’t have an unexpected consequence on the wastewater treatment plant.

There are many enterprises that treat their water. When discharging water to the local municipalities, wastewater treatment plants may not realize that the enterprise contributes anywhere from 5 to 25% of the entire municipal system.

Free checklist!

Use this Word checklist to ensure that your flammable cabinets are safe and secure. Safety includes proper handling of chemicals used for wastewater treatment.

A change that keeps you inside of the scope of your permit can have major effects on how the municipality manages their system. Communication is so critical in this relationship.

The municipality may ask your business to hold off on a proposed change. It may also have additional ideas on how to best work together to make additional changes. This can increase sustainability efforts with both the municipality and your business in the long run.

Fire code standards and system transfer

It’s also important to follow international fire code standards for storing and managing chemicals in large quantities. The management of chemicals for wastewater treatment requires careful documentation, sometimes including a hazardous materials inventory statement (HMIS). According to the ICC, these are the pieces of information you need to include on the HMIS:

- Product name

- Component

- Chemical Abstract Service (CAS) number

- Container size

- Hazard classification

- Location or storage or use

- Amount stored

- Amount in use (closed systems)

- Amount in use (open systems)

In my experience, one commonly overlooked safety step is ensuring that equipment is properly grounded before transferring flammable liquids. This applies whether you’re adding liquid into a system for use or disposing of it at the end of the product’s life.

Because grounding is a simple and low-cost process, I recommend auditing it weekly to verify that any removable grounding devices are securely attached to the equipment.

Training in chemicals for wastewater treatment

Employees who manage wastewater treatment chemicals must complete hazard communication (HazCom) training, as required by OSHA under the GHS standards. Because these chemicals pose unique risks, the training should include detailed guidance on hazard communication protocols.

It must also cover how to properly store, handle, manage, and dispose of chemicals. In addition, employees should learn which personal protective equipment (PPE) is required and who is authorized to work with these substances.

If employees are responsible for disposing of these chemicals as waste, you must also train them in DOT and RCRA regulations. Furthermore, sites operating under an SPCC or SWPCC program should provide specific training on the safe handling of wastewater treatment chemicals.

Hazard communication training course

Check out this free course from our LMS content library to train your workers on the basics of HazCom compliance.

Storage requirements and recommendations

You must store all chemicals onsite in containers and cabinets designed for their specific hazards. For example, place flammable substances in a grounded flammable cabinet, and store corrosives in a grounded corrosive cabinet. When planning chemical storage, always account for the unique requirements of wastewater treatment chemicals.

However, be aware that some cabinets may physically hold more containers than they are rated for. Fitting all your bottles inside doesn’t mean you’re storing them safely or in compliance with regulations.

Flammable and corrosive storage cabinets must display their maximum capacity clearly on the front. Additionally, regulations restrict the number of cabinets you can place in one area unless you install appropriate fire suppression systems or explosion-proof electrical components.

To stay compliant, consult a professional engineer before modifying your storage setup or facility operations. This ensures your process meets local safety regulations from the outset.