There are multiple OSHA regulations concerning fire hazard prevention, especially when it comes to flammable liquid storage best practices. Of course, the goal of these standards is to protect workers from potential injuries.

But these guidelines are also essential for protecting capital assets like buildings, equipment, and expensive machinery (among others). This quick guide covers some examples of substances to protect, OSHA’s recommendations for storage, and some tips for following those recommendations.

Examples of flammable liquids

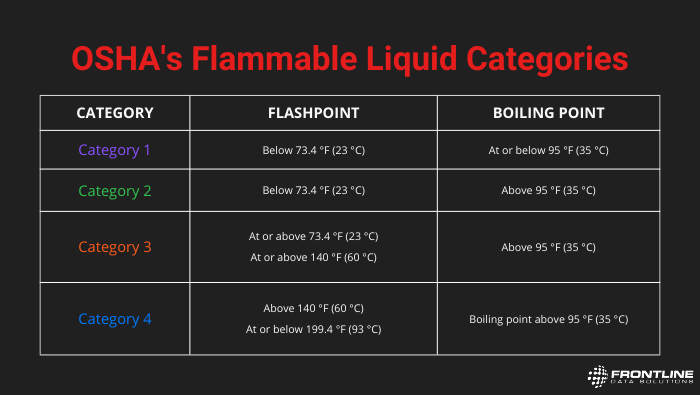

According to OSHA, “a flammable liquid is any liquid having a flashpoint at or below 199.4 °F (93 °C).” These substances are separated into four categories based on their flashpoints and boiling points. You can view those different categories in the graphic below.

Here are some examples of flammable liquids in each of the four categories:

1: Vinyl chloride, heptane, pentane, ethyl ether

2: Gasoline, isopropyl alcohol, acetone, ethanol

3: Kerosene, mineral spirits, diesel fuel, turpentine

4: Mineral oil, oil-based paint, glycerin, ethylene glycol

While general public may not know many of these, others are very common in the industrial environment. Because of the hazards that these liquids pose, it’s important to store them separate from other materials in the workplace.

OSHA’s flammable liquid guidelines

You can find the bulk of OSHA’s flammable liquid storage guidelines in Standard 1910.106 Subpart H: Hazardous Materials – Flammable Liquids. The first portion of the standard lays out important different definitions before going into the requirements.

Then, it goes into specific requirements for different types of storage locations and liquids. Below is a breakdown of each section so you can know exactly where to look. For all the guidelines related to flammable liquids, you should review section 1910.106 in its entirety.

1910.106(b): Tank storage

This includes details on the construction and installation of below and aboveground storage tanks for flammable liquids. Here is where you can find requirements for tank venting, spacing, piping, drainage, dikes, walls, etc.

Under paragraph (b)(5) you’ll find everything you need to know about the correct way to anchor a storage tank and how to build a compliant foundation.

1910.106(c): Materials for piping, valves, and fittings

In this section, you can find information on the components you’ll need to build and anchor your flammable liquid storage tank(s).

1910.106(d): Container and portable tank storage

This section specifically pertains to any flammable liquids stored in portable containers with a maximum capacity of 60 gallons or portable tanks with a maximum capacity of 660 gallons.

1910.106(e): Industrial plants

If your site uses flammable liquids in processes like filtering or mixing (which don’t require a chemical reaction), this section applies to you. It also applies if flammable liquids are a part of the business but not the focus. This section does not apply to chemical plants, refineries, and distilleries.

1910.106(f): Bulk plants

This section provides details on how to receive flammable liquids from tank vessels, tank vehicles, tank cars, or pipelines. It also applies to businesses that store these liquids in bulk for distribution via those channels.

1910.106(g): Service stations

The requirements in this section are for the handling and storage of flammable liquids at service stations. You can find additional guidelines in OSHA Standard 1926 Subpart F: Fire Protection and Prevention. It states that you must store any materials that you use in refueling areas in either:

- Underground tanks

- Aboveground portable tanks

- OSHA-approved closed containers

This helps seal the liquids from ignition sources and ensures that refueling materials are obvious to anyone within proximity.

Best practices for flammable liquid storage

Aside from following OSHA’s guidelines for businesses, it’s also important to teach your workers how to follow safe handling practices. Here are some general tips you can share with your team and incorporate in your training materials:

- Ensure that the area has proper ventilation when opening flammable liquid containers.

- Place empty storage containers in a designated disposal bin, not the general trashcan.

- Keep ignition sources away from all types of flammable liquids.

- Before putting containers back in storage, double check their seals.

- Never leave any type of flammable liquid attended in the workplace.

- Wear gloves, goggles, and other required PPE when handling flammable liquids.

- Always keep storage containers away from heat sources.

Your workers can prevent major fire hazards by following these best practices. To ensure that workers follow your rules, train all new managers how to lead by example and how to positively correct unsafe behavior.