Having a cannabis manufacturing quality control approach in place is essential for protecting public health interests. QA is the set of principles, protocols, and procedures defined by a company that ensures the quality of its products is high and compliant with organizational and regulatory standards.

The regulatory standards in place for cannabis products are aimed at keeping consumers safe and healthy. Although, without federal oversight, states have been left to create regulations for consumer safety all by themselves. States and consumers alike have had to learn the hard way through emerging quality and safety issues.

Understanding both QA and safety principles, along with cannabis manufacturing best practices, is the key to preventing health issues. Without the QA process or a blatant disregard for safety, there is no data to back up a product’s safety.

Cannabis manufacturers will need to identify the potential safety risks and problems that may occur during the manufacturing process in order to plan to prevent them. If there is not a comprehensive QA process in place, the consumer’s safety is at risk.

Free Form!

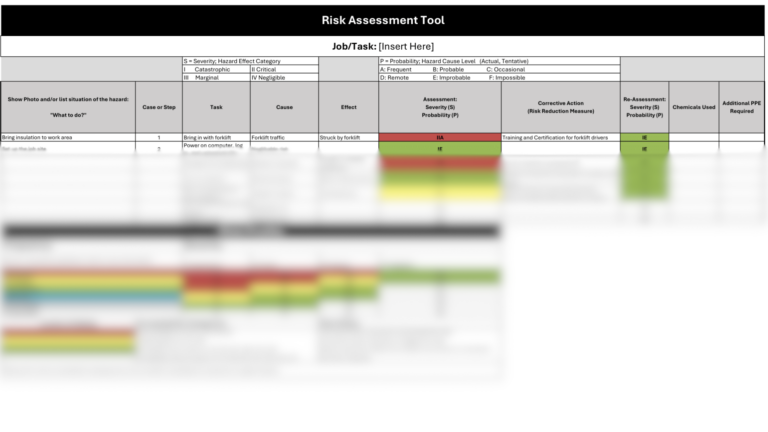

Use this Excel manufacturing risk assessment template to complete a detailed assessment of your processes.

Cannabis Manufacturing Quality Control Issues

Contamination: Contaminants can range from microbial to chemical to physical debris. Microbial contamination is broader concern for unprocessed cannabis while chemical contamination is a concern for processed cannabis products. In August 2019 in Michigan, the Marijuana Regulatory Agency (MRA) issued a health and safety bulletin recalling four products that failed heavy metal testing (arsenic, cadmium, and chromium) and contained chemical residue of bifenazate.

The bulletin indicated the contaminants could cause coughing, wheezing, vomiting, decreased pulmonary function, abnormal heart rhythm, and damage to blood vessels. In January 2021, the Oregon Liquor Control Commission (OLCC) issued recalls for two cannabis products that failed pesticide tests. The health effects of inhaling pesticides are unknown.

Potency and Dosing: There have been issues with potency testing which presents a problem for medicinal cannabis consumers that need to know how strong a product is. A recent study indicated that patients using medical cannabis products had different levels of cannabinoids than expected. These findings were consistent with a previous study that showed discrepancies in concentrations presented on product labels of edible cannabis products in California and Washington.

Cannabis test results from one lab may say one thing and the results from the second lab may say something different even though both labs used the same analytical method. So how do manufacturers rectify and/or prevent these problems from reaching the consumer? By having a comprehensive QA program in place to identify problems noncompliant products.

National Cannabis Quality Assurance Standards

The inconsistency in cannabis testing results and the lack of standard reference materials have held back the QA process. Currently, the National Institute of Standards and Technology (NIST) is developing standard reference material so to develop quality assurance.

The Cannabis Quality Assurance Program (CannaQAP) launched in May 2019 to support the testing of hemp products and the related THC concentrations but has broadened in scope to include testing for toxic elements.

This step towards standardization means there is a path towards the development of concise methods and protocols for testing cannabis. Once a standardized method with standard reference material comes out, we can begin to feel more confident about the quality and safety of cannabis products.

Hazard Assessment and Critical Control Points (HACCP)

If we consider cannabis-infused product safety, the Hazard Assessment and Critical Control Points (HACCP) safety system should be a priority. The HACCP considers three hazard categories:

- Biological Hazards – These can be microbes, like pathogens that cause foodborne illness, or fungal toxins, like mold.

- Chemical Hazards – Presence of residual solvents, heavy metals, pesticides, and other chemical residues.

- Physical Hazards – Debris that is big enough to cause harm, like metal or glass fragments.

Sometime in the future, the federal government may ask cannabis manufacturers to implement an HACCP system or similar practices. The HACCP structure allows manufacturers to consider the steps in the process to identify and eliminate the risk of hazards. This system is one piece of a larger structure of safety programs like standard operating procedures and good manufacturing processes (GMP).

The future of the cannabis manufacturing industry relies on executive teams prioritizing quality assurance and safety. With cannabis manufacturing quality control systems in place, consumers will be safer from health hazards related to oversights.