Compliance within the cannabis manufacturing industry is vital to running a successful operation. Cannabis regulations focus on regulating and controlling the cultivation, harvesting, transport, processing, and sale of cannabis and cannabis-related products.

As more states legalize cannabis, the regulatory landscape will continue to evolve so understanding how to maintain compliance in the changing landscape will be important. The consequences of non-compliance can lead to large fines, suspension of business, and loss of licensure.

Even though cannabis is not federally legal, the federal standards from OSHA are still applicable and required to be followed by cannabis manufacturers. OSHA has been known to inspect cannabis facilities in States where it is legal.

Additionally, inspections will certainly be conducted at the State level. States, where the cannabis industry has been well established, will have specific and structured health and safety regulations in place such as the California Department of Public Heath’s mandates of the Medicinal and Adult-Use Cannabis Regulation and Safety Act.

Below are some tips for manufacturing compliance and a safer work environment for the cannabis industry.

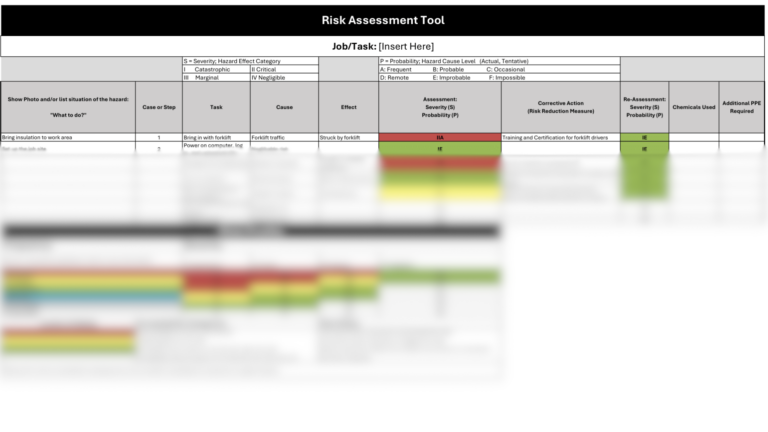

Free template!

This Excel template provides the outline to complete a full risk assessment of your manufacturing processes.

Chemical hazards

Cannabis manufacturing compliance is critical, as a manufacturer may produce a variety of products: cannabis concentrate or extracts, vaping cartridges, capsules, edibles, among many others. Volatile and nonvolatile chemicals used during the extraction and infusion processes are common in cannabis manufacturing.

Some of these processes are riskier because of the use of hazardous chemicals and production of hazardous waste.

Volatile solvents from the processing of cannabis can expose workers to hazardous chemicals and explosive atmospheres. Supercritical carbon dioxide (CO2) along with the application of high pressure creates physical hazards and possible asphyxiation conditions.

The use of volatile chemicals can create explosive atmospheric conditions that may result in a serious injury or life-threatening explosion if not monitored properly, which is what happened in 2018 at a cannabis manufacturing facility in California.

Review your company’s manufacturing processes to identify chemical hazards, exposure points, hazardous waste, and the potential for explosive atmospheres or asphyxiation conditions. Ensure your employees know the process of assessing, monitoring, and correcting emerging hazards. Leverage software to ensure that workers follow your safety processes.

Hazard communication

Cannabis manufacturers must comply with OSHA’s Hazard Communication Standard. Manufacturers need a written Hazard Communication Plan that outlines the business’ compliance with labeling hazardous containers, maintenance of safety data sheets (SDSs), and hazardous materials training for employees.

You must train your employees on hazardous materials before they start work and as you introduce new hazardous materials. This includes training employees to assess, monitor, and identify hazardous conditions. Also, you must maintain a hazard communication plan and have it available for review.

State health and safety regulations

State health and safety regulations play a key role in cannabis manufacturing compliance. Your state may have specific safety and health requirements that OSHA does not. For example, in California, cannabis employers must have a written Injury and Illness Prevention Program (IIPP) that includes procedures to identify and correct hazards.

State regulations on product safety, packaging, and labeling vary by state, so it’s important to understand local laws and monitor changes regularly to maintain cannabis manufacturing compliance.

Recordkeeping

One factor that remains consistent between states in cannabis regulations is recordkeeping. Cannabis manufacturers must maintain records from the initial raw materails to the final product.

Production records provide a means to trace products back to raw materials to identify where a problem has occurred in the manufacturing process that may cause safety or quality issues associated with the consumption of the product. In addition to production records required by the State, cannabis manufacturers with 10 or more employees must comply with OSHA’s recordkeeping requirements for recording and reporting injuries and illnesses.

Good manufacturing practices

Good manufacturing practices (GMPs) is a system of processes, procedures, and documentation for consistent products controlled by quality standards. If you manufacture drugs, medical devices, or food products, you fall into this category.

To remain successful and sustainable, cannabis manufacturers will want to consider implementing GMPs which not only ensures consistent, high-quality products but also consumer health and safety.

GMP guidelines adress issues such as:

- Hhygiene

- Controlled environmental conditions

- Clearly defined and controlled manufacturing processes

- Training

- Records and documentation

- Product recall system

- Providing a system to investigate complaints

Regulations ensure that manufacturers control the safety of their products. Implementation of GMP for a cannabis manufacturer would include evaluation of potential risks to the safety and quality of the cannabis product.

These risks could include biological, chemical, and physical hazards like microbe contamination, presence of a residual solvent or other residues, cross-contamination and introduction of allergens, presence of foreign materials like metal fragments, hair, insects, etc. Consider bringing in a GMP consultant to ensure proper implementation.

Waste management

Most, if not all, cannabis manufacturing processes produce some form of waste, ranging from organic to hazardous. You can compost organic plant materials as long as they are not mixed with hazardous or toxic substances.

For cannabis manufacturing compliance, cannabis waste is classified as hazardous if it is listed under federal regulations or exhibits hazardous characteristics such as ignitability, corrosivity, reactivity, or toxicity.

This may include waste solvents (e.g., propane, ethanol, butane), process waste contaminated with solvents, used reactants, or compressed gases. You must dispose of this waste through approved hazardous waste facilities.

Cannabis manufacturers need to characterize their waste for appropriate disposal. Reach out to your local solid waste and hazardous waste facilities to understand appropriate disposal and the volume of waste they will accept.

The compliance issues discussed cover a broad base but are not exhaustive. The cannabis manufacturing industry is evolving along with regulations. It is important that manufacturers proactively and regularly review regulations to ensure compliance by considering both federal and state laws.