What Is Management of Change (MOC)?

Frontline Data Solutions: Safety Simplified

Free MOC Compliance Guide to Help You Get Started

Download our MOC Compliance Guide, which breaks down OSHA’s management of change requirements in greater detail. This guide will help you understand what’s required to meet compliance and give you practical tips for improving your MOC program.

Chapter 1: What Is Management of Change (MOC)?

Management of change (MOC) is a formal process for evaluating, documenting, and controlling modifications to processes, equipment, chemicals, technology, or personnel that could affect safety or operations. It’s a foundational requirement of the OSHA’s Process Safety Management (PSM) standard, 29 CFR 1910.119.

While management of change most commonly applies to high-risk industries like chemical manufacturing or oil and gas, engineering, operations, and EHS management teams across all types of companies. At its core, MOC is about minimizing risks, controlling costs, and protecting people.

Read our post “The 14 Process Safety Management Elements” to see the full list of OSHA’s requirements.

OSHA’s MOC Requirement

Under the PSM standard, you have to establish and implement written procedures for managing changes (excluding “replacements in kind”) that could affect a covered process. These changes may include:

- New or modified equipment

- Process technology updates

- Facility layout changes

- Raw material substitutions

- Changes in instrumentation or control logic

- Personnel or organizational shifts impacting operations

The purpose of management of change is to prevent incidents by forcing you to pause and assess risks before introducing changes. It helps ensure proper review, documentation, training, and operational updates.

Why MOC Matters for Businesses

Uncontrolled changes are one of the most common root causes of industrial accidents. In the absence of an MOC process, risks are harder to control.

Take the example of swapping out a valve. Without MOC, your team might not realize that the new valve alters the equipment’s pressure relief settings.

[Get our free Pressure Valve MOC Form!]

By documenting and reviewing each proposed change in a structured workflow, you can:

- Reduce the risk of unintended safety consequences

- Improve regulatory compliance (especially under OSHA and EPA)

- Strengthen operational consistency and communication

- Protect workers, facilities, and the surrounding community

Without an effective MOC system in place, even well-intentioned changes can expose your process and people to more risk. This potentially leads to injuries, environmental releases, or regulatory violations.

Who Needs an MOC Program?

Management of change is a mandatory component of PSM for facilities that handle highly hazardous chemicals (HHCs) above threshold quantities. These include substances like:

- Anhydrous ammonia

- Hydrogen sulfide

- Chlorine

- Flammable gases and liquids

- Acids and oxidizers used in production

Check out the full list of highly hazardous chemicals to see if your company falls under the PSM requirements.

However, even facilities that aren’t subject to PSM often implement MOC programs to ensure operational safety and consistency when changes occur. Companies in utilities, food and beverage, aerospace, and discrete manufacturing use management of change to avoid introducing risks or costly errors into their systems.

Whether your goal is to comply with OSHA’s PSM rule or adopt safer operational practices, a strong MOC program is essential for managing risk in complex environments.

Free Form!

Download this free management of change form to see what information you need to document for covered changes.

Chapter 2: Why Management of Change Is Challenging

Even though MOC is critical for safety and compliance, it’s often one of the hardest programs to get right. Disconnected systems, informal workflows, and limited visibility can lead to dangerous oversights. Overcoming these challenges requires structure, tools, and a culture that values accountability and proactive risk management.

Complex Processes and Interdepartmental Communication

Managing change effectively requires coordination across departments like operations, maintenance, engineering, safety, quality, and HR. In many companies, these teams operate in silos. When you introduce changes without cross-functional visibility, it’s easy to miss compliance requirements or overlook risks. If changes affect multiple departments or locations, it can be difficult to execute consistently without a formal MOC program.

Informal or Inconsistent Workflows

Another common challenge with management of change is informal processes. Using spreadsheets, emails, and forms to track changes isn’t great because it creates a lot of gaps. This sort of approach can stall out your approval process or make it harder to find important compliance documents. Plus, it gets increasingly harder to maintain document control.

Over time, this creates more work, bigger compliance gaps, and less accountability. Long-term, it means that you might have more uncontrolled risks than you think you do, all because you didn’t document and monitor them properly.

Documentation and Audit Burden

Compliance with OSHA’s PSM standard requires detailed documentation of every change. You must include things like:

- Impact analysis

- Approvals

- Updates to procedures

- Confirmation of training

What makes this harder is having the information scattered across formats or systems. Because when a program audit happens, you might struggle to prove that a change followed the correct process and that employees received the correct training.

Read our post “Updating Control Documents for PSM Compliance” for more details.

Resistance to Change and Lack of Buy-In

Another challenge is employee buy-in. Workers often resist additional layers of paperwork or oversight, especially in industrial environments where speed and flexibility are rewarded.

Your team may feel like the management of change process slows them down or doesn’t apply to certain changes. Without strong leadership support and ongoing training, they won’t view MOC as a vital safety measure worth following.

Lack of Visibility and Oversight

One of the most important keys to success with MOC is program visibility. If you don’t know which changes your team is working on and the status of those changes, it’ll be difficult to ensure compliance.

Aside from the reporting challenges, a lack of oversight often renders MOC programs ineffective. The whole point of having this process in place is to oversee implementation and eliminate risks. So, if you don’t have an overall view of what’s happening, then you can’t proactively control risks in real time or monitor them after changes go into effect.

Chapter 3: Best Practices for Managing Operational Changes

Improving how your team manages changes comes down to structure, clarity, and collaboration. Some of the keys to success are defined roles within the MOC program, standard workflows to meet compliance requirements, and high-quality documentation practices. When you involve the right people and oversee follow-through, management of change becomes a major win instead of a burden.

Create Written Procedures Aligned with OSHA’s PSM Elements

One of the most effective ways to improve your management of change process is to formalize it with written procedures that align with OSHA’s PSM standard. Your procedures should outline answers to questions like:

- When do changes need to go through the MOC process?

- Who is responsible for each step in the process?

- What documentation should each change have?

- How should employees assess hazards?

- When and how should safety procedures be updated?

Written MOC procedures should also explain how your team will verify training compliance and close out changes. Just the exercise of writing our your MOC plan is great for getting your team aligned and ready to meet compliance requirements. Plus, it reduces the risk of miscommunication and gives you something to fall back on when you fall out of sync or out of compliance.

Create a Standardized MOC Process

Another best practice is to introduce standardization across your MOC activities. That’s because variation in your approach can lead to gaps that increase risk of noncompliance or process safety incidents.

Here are some quick tips for standardizing management of change:

- Put together a management of change department or committee that oversees all PSM-covered changes.

- Build an MOC workflow that outlines the required steps each change must follow.

- Create a standard naming system for all MOC documents that’s simple to stick to.

- Use management of change software to close compliance gaps and organize compliance documentation.

The more guesswork you can take out of your MOC program, the easier it will be to maintain long-term. If you approach every single change with the same approach, then you’ll get faster at processing change requests and implementing them without sacrificing compliance.

Classify and Prioritize Risks

Not every change carries the same level of risk. Some changes require lots of resources to implement while others may take only a few days. That’s why having a classification system is important. It allows you to prioritize your MOCs, so you can allocate your resources to the most critical ones.

Your classification system can be simple. For example, categorize changes into ones that are required under the PSM standard and those that aren’t. For the non-PSM changes, you’ll have less documentation requirements and so may choose to have a simpler MOC process. You can also classify changes according to their potential risk level and which area(s) of the business they impact.

Good management of change programs should automatically trigger required tasks like approvals, hazard reviews, procedure updates, and training verifications based on the type of change. But don’t forget about follow-up tasks as well. Even after you implement a change, you must verify that your team has updated documentation, that equipment functions properly, and that you’ve notified your employees.

Encourage Cross‑Functional Collaboration

Effective MOC doesn’t happen in isolation. It requires collaboration between operations, safety, maintenance, engineering, and compliance. Each department brings a unique perspective that’s vital for identifying and mitigating risk.

Regularly including cross-functional teams in the MOC process is the best way to make sure your team doesn’t miss any critical information. Input from the operations team, for example, can help uncover a production issue with a new process layout. Or feedback from the safety team can help prevent an incident from a new equipment design from engineering.

Without collaboration, you’ll always have blind spots in your operation. And if you want to make the best decisions for your bottom line, you need to remove blind spots wherever possible.

Todd Energy Scaled Its PSM Program with Frontline MOC

Todd Energy used Frontline MOC to overhaul their PSM compliance program, and now they’re able to management hundreds of changes at once.

Chapter 4: Applying MOC Beyond PSM Compliance

MOC is the best practice for any company that wants to maintain operational control and reduce safety risk during change. Whether you’re PSM-covered or not, adopting the principles of MOC is a smart investment in both compliance and company culture.

MOC Isn’t Just for PSM-Covered Facilities

OSHA’s PSM standard specifically requires an MOC program for facilities handling highly hazardous chemicals. But that doesn’t mean management of change can’t apply to other industries. In fact, the principles of MOC provide tons of value to any type of business, which is why more companies are adopting the framework for change management.

Here are some of the non-PSM changes you can manage with your MOC program:

- Introducing new products or updating existing products

- Rolling out a PR campaign

- Implementing quality control measures

- Making changes to your organizational chart

- Business mergers and acquisitions

- Building or equipment maintenance procedures

Essentially, you can use MOC to oversee any change that might affect overall business performance. This includes areas like safety, quality, productivity, customer relations, brand perception, and more.

Why MOC Still Matters Without a Legal Requirement

Even if your facility isn’t legally required to follow OSHA’s PSM standard, implementing MOC procedures provides major benefits. First, it protects against unintentional risk. Unmanaged changes can cause accidents, quality issues, downtime, or regulatory violations. Second, MOC encourages cross-departmental collaboration and keeps your team aligned. Lastly, having an MOC system demonstrates proactive risk management, which can enhance audit performance, lower insurance costs, and build trust with stakeholders.

For companies that aren’t bound by strict PSM rules, the flexibility to scale MOC processes is key. A digital solution that allows you to tailor workflows, define your own risk categories, and configure notifications makes it easy to apply MOC where it adds value without unnecessary complexity. This lets you implement a risk-based approach, applying a full MOC process only when warranted while keeping smaller changes on your radar.

Chapter 5: Frontline MOC Software is a Game-Changer

Frontline MOC is the best management of change software solution on the market for handling operational changes. It’s configurable for managing both PSM and non-PSM related changes. From improving compliance to reducing risk, it’s the system you need to take your MOC program to the next level.

Streamlined Change Management from Start to Finish

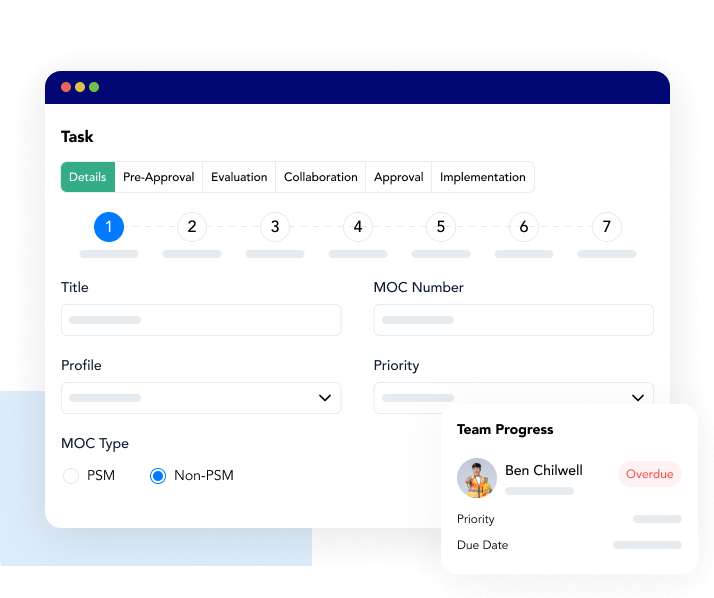

Frontline MOC software automates and simplifies the management of change process from initiation to closeout. Our best-in-class MOC workflow has both optional and required stages, so you can configure each change to match the level of risk. For more complex and higher-risk changes, use the optional stages to add extra verifications.

Starting from the pre-approval stage, MOCs go through documented approvals and reviews to ensure full buy-in before implementation. The system allows you to assign and track both action items and training related to the changes, so your team can stay ahead of deadlines.

At the end of the process, you have a full record of all the decisions, action items, and stakeholders involved in bringing the change to life. This automation removes the manual burden of documentation so you can focus on executing safe and compliant changes.

Built-In Compliance Tools and Visibility

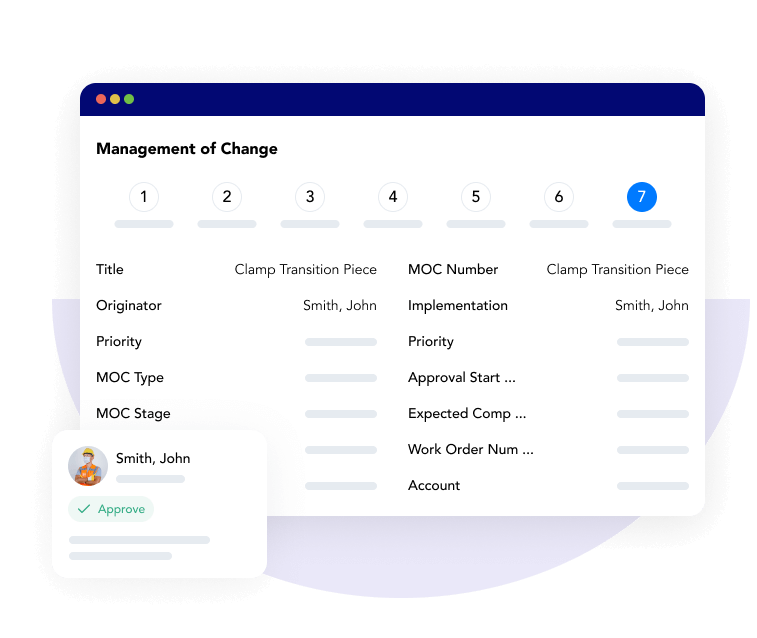

Regulatory readiness is built into the foundation of Frontline MOC. The platform automatically generates audit-ready records with time-stamped actions, version control, and complete change histories.

The analytics dashboard shows you the real-time status of all active and completed changes, helping you stay on top of deadlines and follow-ups. And with email alerts and task notifications, you’re able to keep your team engaged and following MOC steps in order.

Having management of change software makes it easier to stay organized with your compliance requirements. This is especially true if you’re managing lots of changes at once. With everything in one place, you can always be sure of where your MOC program stands.

Collaborative Workflows That Close Gaps

What sets Frontline MOC apart from competing software systems is its emphasis on collaboration and consistency. The system enables users from different departments to contribute to changes within a shared workflow. Role-based permissions and defined responsibilities make sure that the right people in your company are always in the loop at the right time.

A major benefit of Frontline MOC is that it eliminates the need to rely on manual tracking processes. This, in turn, lowers risk by preventing human error and improving accountability across the board.

Whether you’re operating under OSHA’s PSM standard or simply trying to create a safer, more controlled workplace, Frontline MOC delivers a scalable solution that supports both. Its user-friendly interface and mobile capabilities make adoption easy, so you can manage even the most complex changes with ease.

Ready to Simplify Compliance with Frontline MOC?

Book a personalized demo with our team to explore how Frontline Data Solutions can help you increase visibility, improve compliance, and reduce risk in one intuitive platform.