Process safety management of highly hazardous chemicals is vital to any facility’s safety and health plan. This type of process safety management includes identifying highly hazardous chemicals, gathering process safety information, performing initial and updated process analyses, and setting safe operating procedures for workers.

What are highly hazardous chemicals and processes?

A highly hazardous chemical means a substance possessing toxic, reactive, flammable, or explosive properties. These include chemicals at or above the specified threshold quantities listed in 1910.119 App A and processes involving more than 10,000 pounds (4,535.9 kg) of a Category 1 flammable gas or a flammable liquid with a flashpoint below 100 °F (37.8 °C) on-site in one location.

In this case, a process means any activity involving a highly hazardous chemical, including any use, storage, manufacturing, handling, the on-site movement of such chemicals, or a combination of these activities. Therefore, any group of interconnected and separate vessels that are located such that a highly hazardous chemical could be involved in a potential release is considered a single process.

Why is the process safety management of highly hazardous chemicals a priority?

Firstly, the goal of process management of hazardous chemicals is to prevent or minimize the consequences of catastrophic releases of toxic, reactive, flammable, or explosive chemicals. Secondly, these releases may create toxic, fire, or explosion hazards. Finally, a catastrophic release refers to a significant uncontrolled emission, fire, or explosion involving highly dangerous chemicals.

Additionally, highly hazardous chemical management does not apply to oil or gas well drilling or servicing operations. Furthermore, it does not apply to normally unoccupied remote facilities. Finally, a normally unoccupied remote facility is operated, maintained, or serviced by workers who visit only periodically to check operations and perform necessary tasks, which lowers overall exposure to processes.

What is a process hazard analysis?

Process hazard analyses are hazard evaluations that identify, evaluate, and control the process’s hazards. The employer shall perform an initial process hazard analysis appropriate to the process’s complexity on the processes previously defined. Employers shall also determine and document priority order for conducting process hazard analyses based on considerations such as the extent of the process hazards, number of potentially affected workers, age of the process, and operating history of the process.

The employer shall use one or more of the following methods to determine and evaluate process hazards: what-if, checklist, Hazard and Operability Study (HAZOP), Failure Mode and Effects Analysis (FMEA), fault tree analysis, or another appropriate equivalent method.

Process hazard analyses shall address: hazards of the process, identify any previous incident with likely potential for catastrophic consequences in the workplace, engineering and administrative controls applicable to the hazards and detection methods, consequences of a failure of engineering and administrative controls, facility siting, human factors, and qualitative evaluation of a range of possible safety and health effects of failure of controls on workers.

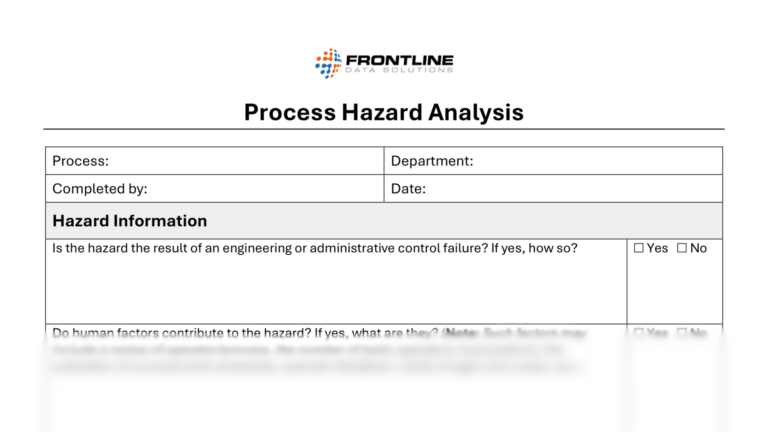

Free form!

Use this process hazard analysis form template to work on your own worksite reviews.

Who should perform process hazard analyses?

A team shall perform process hazard analyses with expertise in engineering and process operations, including at least one worker with experience and knowledge specific to the process being evaluated and one member who knows the specific process hazard analysis methods being used.

How often should we perform analyses?

Every five years after completion of the initial process hazard analysis, the analysis shall be updated and revalidated by the qualified team to assure that the existing analysis is consistent with the current process.

So, what process safety information is required?

What are the process safety information requirements?

The employer shall complete a compilation of written process safety information before conducting any process hazard analysis required by the standard. Accordingly, the compilation of written process safety information enables the employer and workers involved in operating the process to identify and understand hazards posed by processes involving highly hazardous chemicals.

This process safety information includes:

- Information about the hazards of the highly hazardous chemicals used or produced by the process

- Information on the technology of the process, and

- Information of the equipment in the process

Hazard information consists of at least the following:

- Toxicity information

- Permissible exposure limits

- Physical data

- Reactivity data

- Corrosivity data

- Thermal and chemical stability data

- Hazardous effects of inadvertent mixing of different materials

Additionally, information concerning process technology must include:

- Block flow or simplified process flow diagram

- Process chemistry

- Maximum intended inventory

- Safe upper and lower limits for such items as temperatures, pressures, flows

- Evaluation of the consequences of deviations, including those affecting the safety and health of employees.

Also, information of the equipment in the process shall include:

- Materials of construction

- Piping and instrument diagrams (P&ID’s)

- Electrical classification

- Relief system design and design basis,

- Ventilation system design

- Design codes and standards employed

- Material and energy balances

- Safety systems

The employer shall document that the equipment complies with recognized and acceptable engineering practices. In particular, employers must determine and document that the equipment is designed, maintained, inspected, tested, and operating safely for existing equipment designed and constructed following codes, standards, or practices no longer in general use.

What are safe operating procedures in process safety management of hazardous chemicals?

Safe operating procedures provide clear instructions for safely conducting activities in each process consistent with the process’s safety information. Additionally, the procedures must be readily available to employees who maintain the process or work in the process.

The employer shall develop and implement procedures addressing at least the following dealing with highly hazardous chemical processes:

- Initial startup

- Normal operations

- Temporary operations

- Emergency shutdown

- Emergency operations

- Normal shutdown

- Startup following a turnaround

- Operating limits

- Consequence of deviation

- Steps required to correct or avoid deviation

- Safety and health considerations

- Properties of and hazards presented by the chemicals

- Precautions and control measures necessary to prevent exposure

- Safety systems and their functions