Engineering controls can fail for several reasons, but the root cause often traces back to human factors. In order to have the correct engineering controls you must have completed a comprehensive risk assessment. You should complete this assessment even before purchasing equipment for your facility. Base all equipment purchases and installations on the findings of the risk assessment.

Free form!

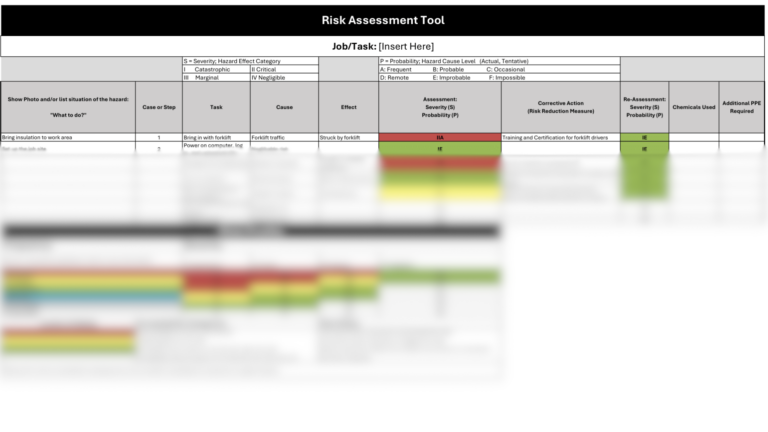

Download this manufacturing risk assessment Excel form to complete your own audits.

Maintenance in engineering controls

Engineering controls may fail if the equipment or device is installed incorrectly or lacks proper maintenance. During the risk assessment, identify how the maintenance program handles installation and upkeep. Mechanical integrity is just as critical to a facility as safety and environmental programs—and it requires the same level of attention to detail.

Bypassing an engineering control

Another aspect of engineering control failure is when operations/management bypasses an engineering control. A facility must have a strong procedure (Management of Change) dealing with any and all bypasses involving an engineering control or any piece of equipment. Operations personnel should involve management when making decisions related to engineering controls. How critical the device/equipment is to the process will dictate how far up the management ladder you should go for approval.

In this procedure, there should be specific instructions on how to handle all levels of bypasses. There should also be a log of some type to keep track of the bypass in order to not let the situation linger on for too long. There should also be time periods for the bypass based on the critical status of the equipment/device.

The decisions for making the bypass should be a group decision between operations, safety, automation, maintenance, and management. During the decision-making process, you may need to conduct a process safety analysis, depending on the level of risk involved. Some companies have these bypass scenarios already in place and that makes the decision process a little easier and faster.

If the bypass could impact the environment, consult the environmental group before proceeding.

Lack of knowledge and training

A very important part of why engineering controls fail is employee involvement. If employees aren’t informed about the change, they may unintentionally cause the control to fail simply because they lack the knowledge needed to perform their job effectively. That’s where the management of change (MOC) comes into play. When a process changes—whether or not it involves an engineering control device or equipment—managers must communicate the change to operations employees. A strong MOC process generates a document for all involved employees to review and sign, confirming their understanding. It also gives them a chance to ask questions and raise concerns before implementing the change. Through this process, employees actively acknowledge and sign off on the change.

Engineering controls can also fail when workers have not received proper training and don’t know how to use or maintain the machinery. This training must be accompanied by supervision and remedial actions if workers are found not following safety protocols. This training should come before involved employees start work in their area of operations but also

updates as things change in the field.

Ensure your team has the right tools and knowledge discussed above to prevent engineering control failures.