Combustible dust is a fine, dry material that can become a potential fire or explosion hazard when suspended in the air at sufficiently high concentrations. You can look at the combustible dust classification to identify the hazards related to these materials. Combustible dust classifications are essential in understanding these hazards.

Understanding combustible dust classifications helps determine the safety procedures necessary to protect employees.

Combustible Dust Explosions

For a fire to occur, we know that there needs to be a “fire triangle”:

- Fuel

- Oxygen

- Source of ignition

For a dust explosion to occur, there has to be a “dust pentagon”, as the NFPA calls it. These combustible dust classifications are very crucial in identifying subsequent risks.

- Dispersion of dust particles

- Confinement of the dust cloud

Explosions are an extreme hazard because they can cause serious injuries or death. They can occur when combustible dust is present in improperly-ventilated areas. When a source of ignition, such as a spark from static electricity or friction ignites the dust cloud, it creates an explosion. Understanding combustible dust classifications helps prevent these incidents.

There are two types of explosions: deflagration and detonation.

Deflagration is a fire that burns at a subsonic speed with flame visible throughout its length.

Detonation is an explosion that occurs without preliminary decomposition and without flame propagation. It results in pressures so high that shock waves destroy structures before ignition takes place.

Examples of Combustible Dust

- Wood dust

- Metallurgical dust (Metals)

- Plastics, rubber, and synthetic materials

- Chemical combustible dust

- Food and agricultural products

- Waste, by-products, and recyclables

Combustible Dust Classifications

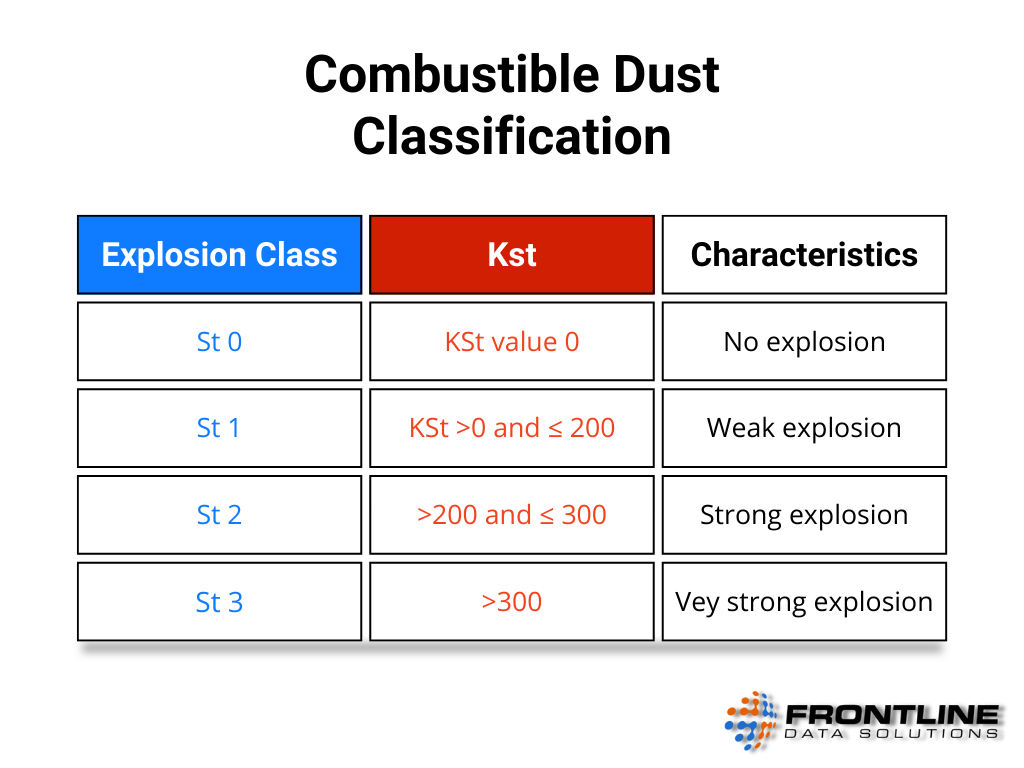

There are different parameters to consider when it comes to combustible dust classification. For instance, Pmax and Kst are among the most common measurements of explosion severity and combustible dust safety.

Pmax

The term Pmax refers to the maximum amount of pressure and damage combustible dust can cause in a confined space. Basically, this measurement allows you to understand the potential damage your dust can create in a confined space. Combustible dust classes include these measurements to ensure effective risk assessment.

Kst

Kst refers to the rate of pressure increase as a dust explosion occurs. Determining which “St Class” your material falls in provides valuable data to help mitigate dust explosion hazards.

- St 0 – KSt value 0 | no explosion

- St 1 – KSt >0 and ≤ 200 | weak explosion

- St 2 – KSt >200 and ≤ 300 | strong explosion

- St 3 – KSt >300 | very strong explosion

Class II Locations

Combustible dust also applies to the NEC’s (National Electrical Code) Hazardous Locations Classification.

These hazardous locations are defined as “an area at risk of fire or explosion due to:

Flammable gases or vapors (Class I)

Combustible dust (Class II)

Fiber or flyings (Class III)

In Class II locations, there is a sufficient amount of combustible dust in the air which can be explosive or ignitable. It includes two divisions:

Division 1 is an area where combustible dust can exist under normal, everyday operating conditions. On the other hand, Division II is an area where combustible dust mentioned above is not likely to exist during regular operation.

Determining the Pmax and Kst of the material along with the Class and Division of the work area can help understand the impact of a potential hazard while providing insight into the elimination or substitution of the risk. That’s why it’s critical to administer combustible dust classification training in the workplace, ensuring that all combustible dust classifications are thoroughly understood by the workforce.