The process of generating energy involves key variables like heavy machinery, environmental elements, and a specialized workforce to keep operations running smoothly. And regardless of the final output, all renewable energy companies face the challenge of carefully managing any changes to these variables.

If you work in the renewable energy industry, adopting the principles of change management can help you better coordinate complex modifications to processes your workers use every day. That means you’re less exposed to risks like safety incidents or operational downtime, saving you money in the long run.

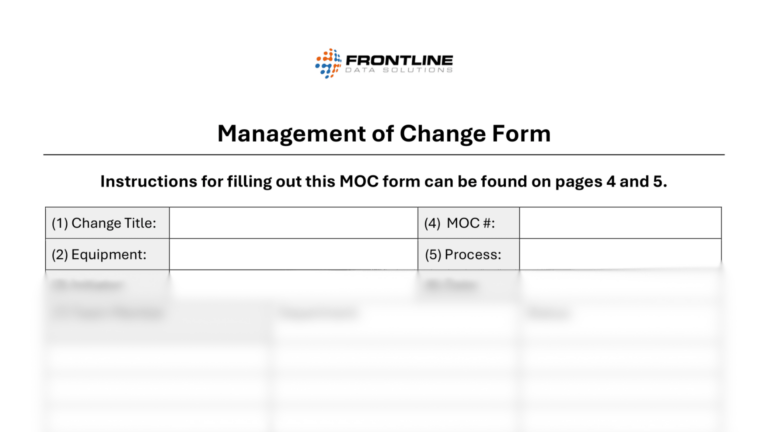

Free form!

This form will walk you through the basic steps of the change management process.

OSHA PSM compliance

Many operations in the non-renewable energy industry fall under OSHA’s process safety management (PSM) requirements. The goal of PSM is to prevent the unexpected release of highly hazardous materials like hydrogen sulfide and nitric oxide.

The full list of mandatory chemicals, toxics, and reactives contains more than 130 materials. And processes that involve these materials must ensure continued compliance with the OSHA standard.

One key element within the PSM standard is management of change (MOC), a process for carefully executing modifications to processes, equipment, and personnel.

Most players in the non-renewable energy sector fall under this standard, but not all renewable energy companies do. But if you think about management of change as a tool to improve your entire operation, rather than a regulatory burden, you can quickly find many areas to apply it.

Advantages of the change management process

A change management process is a standard approach for implementing modifications to your existing systems. It involves a few key steps:

- A change request is made.

- Stakeholders review the change request and decide whether to approve or deny it.

- An implementation team completes all the required tasks and reviews them.

- The change goes into effect throughout the entire facility/organization.

If properly implemented, this process provides several key benefits to energy companies.

Prevention of system failures

When you make modifications to your operations, the risk of system failures increases. If you don’t have full oversight of those changes, these risks can skyrocket without your knowledge.

Change management helps prevent system failures by establishing critical checks in the implementation process. Through the process of approval, collaboration, and review, your team has the opportunity to consider weak points where a system failure might occur.

Reduction of downtime

Downtime is a natural byproduct of making changes to how you do things. If not full-on downtime, your operation will likely experience a period of decreased productivity while changes go into effect. With a change management tool, you can reduce the length of this downtime by performing checks before you roll out an entire change.

Take the example of introducing a new piece of equipment into a process. If you simply buy the equipment, start it up, and then see what happens, you have a greater risk of failure resulting in costly downtime.

Instead, the MOC process guides you through the project so that by the time you get to the end, you’re sure that the equipment is safe, working properly, and ready to start up. This can greatly reduce or eliminate the total downtime that occurs when you finally implement a change.

Full oversight of complex processes

Energy generation is no different from any other production environment in the sense that it involves complex processes. The last thing you want is for your workers to make their own decisions regarding the flow of those processes—without at least a review of the impact.

You can use change management as a means of reviewing even small modifications to complex processes. This gives your team a way to document the approval workflow so you can always trace the origin of certain changes or steps in your processes.

Management of heavy equipment

Heavy equipment is a pain to manage for most companies because it:

- Needs consistent care and upkeep

- Can cause major disruptions to operational performance

- Poses safety risks to workers

That’s why it’s so important to keep an updated equipment log and ensure that you inspect and test new machines properly before introducing them into your operations. The change management process helps ensure careful management of these assets, so they don’t negatively affect the business.

Large-scale change implementation across multiple locations

Renewable energy companies, for the most part, have complex operations with many moving parts. And they face similar regulatory obstacles to their non-renewable counterparts.

As the Environmental Protection Agency (EPA) puts it:

“Large-scale renewable energy technologies are subject to all the necessary environmental permits of major industrial facilities. Renewable energy generation using new technologies can face permitting hurdles until permitting officials are familiar with the environmental effects of the generation processes.”

And that means that companies in the renewable energy industry must be prepared to implement changes carefully and efficiently.

When you’re dealing with one facility, process modifications might not seem overwhelming. But once you get into field operations, changes aren’t so easy to track. To coordinate complex projects, you’ll need a change management process in place.

Imagine that you manage multiple hydroelectric facilities, and you decide to change a step in one of your core processes. Traditionally, each facility would end up having its own way of doing things. With a dedicated approach, however, you can institute a standard process across all your power stations.

If everyone in your organization followed the same process to make major changes, how much more control would you have over performance?

When a new EPA requirement goes into effect and impacts your operations, you can implement any changes using MOC software. That way, you have full control over how your company adapts to new technologies, processes, regulatory requirements, and more.

Frontline MOC client webinar with Todd Energy

Learn from James Grunsell of Todd Energy how they use our MOC software to manage hundreds of changes at once.

Uses of MOC software in the renewables sector

Change management software, like Frontline MOC, helps companies in the renewable energy industry tackle both regulatory compliance and risk management strategies at the same time.

It does this by providing a structured workflow for your team to use when they make any changes to existing systems.

You can use this software when you’re:

- Introducing new pieces of equipment to your operation

- Modifying the variables within existing processes

- Onboarding new employees

- Approving personnel changes

- Implementing new processes

- Making changes to satisfy regulatory requirements

Say you wanted to create a new requirement that your team must perform an equipment inspection before they used a specific piece of equipment. Before you can implement this change, you’d need to review how it might impact the current system. For example:

- How will current employees be trained to complete this inspection?

- Will you need to update your current training materials?

- Will the new inspection create downtime that affects output?

- If workers identify an issue during their inspection, what would be the next step?

- Does the inspection impact use of the equipment in any way?

The biggest benefit of having a software workflow to follow is that it forces you to consider these types of questions before you take action. That allows you to catch unforeseen consequences of the changes you want to make.

So, once you finally figure out how you’re going to proceed with the changes, you’ve already identified and mitigated most of the risks.

With a software tool, you don’t have to worry about getting everyone on the same page. Since approvals and collaboration requirements are built into the workflows, all you have to do is follow them. And this allows you to track all kinds of changes—from replacing or upgrading equipment to reorganizing or overhauling your processes.

That way, you can spend less time keeping your team organized and more time working on the actual implementation of your goals.

Other posts you might like…

No posts