Before purchasing any guardrail systems for your facility, make sure you know what to look for. OSHA requirements for guardrails aren’t complicated, but they are specific. They cover things like the sizing, positioning, and material composition of railing. Review the requirements below and ensure your guardrails comply.

The basics of OSHA guardrail compliance

A “guardrail” is a permanent fixture that prevents people from going past an established walking-working area. Installing guardrails is essential in areas where people aren’t likely to be wearing fall harnesses but could be at risk of a fall from heights. Some examples of this include:

- Runways and ramps

- Access points like holes (where someone would be on a ladder)

- Elevated platforms

- Mezzanine and gallery areas

But simply having a guardrail doesn’t necessarily protect anyone walking in these areas. If the railing isn’t sturdy enough to handle force, then it can cause injuries and accidents. That’s why OSHA has constraints for the construction of guardrail systems. You can find OSHA’s guardrail requirements under standard 1920 Subpart D.

Below, we break down this standard into its various components. Make sure to read through all the requirements so you don’t miss a critical piece of information.

Guardrail measurements

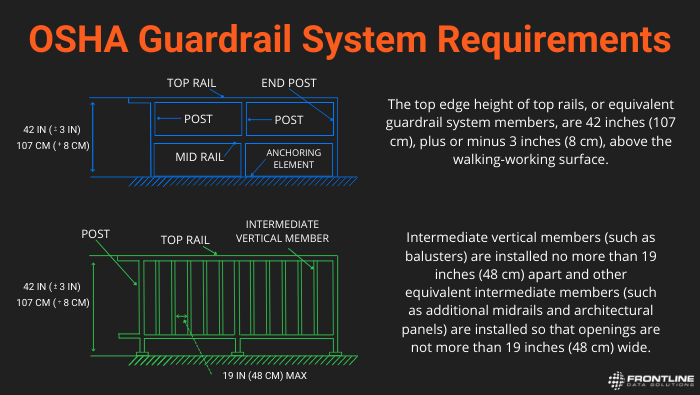

You want to ensure that your guardrails are tall enough to prevent employees from accidentally crossing the walking-working surface. Here are OSHA’s requirements for guardrail height:

The top of the rail system must be 42 inches (±3 in.) from the surface of the walking area.

Any vertical intermediate members (EX. balusters) can be a maximum of 19 inches apart. The same width maximum goes for any other posts within the guardrail system.

All top rails and midrails need to be at least 0.25 inches thick.

In the diagram below, you can see the side profile of two different types of guardrails:

The first option shows a guardrail system with a horizontal midrail and center post. The second shows an option with vertical balusters. Both styles follow OSHA guardrail requirements by having a height of 42 inches. The second option follows the 19-inch maximum distance between vertical posts.

If you’re building a guardrail yourself, make sure your designs account for these limits. If buying guardrails commercially, you shouldn’t have to worry about the design passing OSHA’s guidelines. However, you still need to oversee the construction and ensure that all pieces are the proper distance from the walking surface and each other.

Guardrail materials

Most guardrails are made from sturdy materials like metal and wood. You may choose a different material, however, if it meets OSHA’s strength requirements.

Standard 1920.29 includes two very specific points about the strength of guardrail materials.

1: “Guardrail systems are capable of withstanding, without failure, a force of at least 200 pounds (890 N) applied in a downward or outward direction within 2 inches (5 cm) of the top edge, at any point along the top rail.”

2: “When the 200-pound (890-N) test load is applied in a downward direction, the top rail of the guardrail system must not deflect to a height of less than 39 inches (99 cm) above the walking-working surface.”

This means that you need sturdy materials. While wire and cable guardrails might look nice, they must be safe as well. Manila and synthetic rope can be used for top and midrails as long as they can handle the required 200-pound force.

OSHA requirements for guardrails also state that you need to use a smooth material for the handrail. This is to prevent hand injuries, clothing snags, etc. from happening.

OSHA requirements for guardrails around holes

Unlike traditional walking surfaces, holes are a bit more unexpected for the average worker. That’s why OSHA requires guardrails around all unprotected sides and edges of holes.

Guardrails around holes need a gate that slides or swings away from the hole. They also need to follow one of these two conditions:

- Have an intermediate member of some kind (top rail, midrail, etc.)

- Be offset from the hole to stop anyone from accidentally falling in

If you’re passing objects through a hole, you can’t remove more than two guardrails from the unprotected sides. And when you’re not actively passing items through, you need to either put guardrails around the sides or to cover the hole.

Ensuring compliance

Now that you know OSHA requirements for guardrails, it’s important that you assess your current systems. Make sure to measure for height compliance. Check vertical components for width maximums. And provide anyone working near a hole with the resources to set up a proper guardrail system.

To track guardrail compliance and all other forms of OSHA requirements, consider a digital tracking system. With EHS software, you can compile all your reports, hazard assessments, and OSHA compliance documents in one spot.

If you find during one of your assessments that a guardrail isn’t in compliance, you can simply create an action item to fix the problem quickly. And once it’s complete, you’ll have a detailed record of your finding and resolution of the issue.