The future of EHS compliance lies in cloud-based software

There’s no “right” way to manage safety data and documents. But that doesn’t mean that any system will do. Finding the right combination of tools and procedures can drastically increase the efficiency and quality of your EHS compliance approach.

Oftentimes, small to midsize organizations use traditional methods of data reporting and analysis. Many companies simply improvise their approaches. They use methods like paper documentation and in-house Excel files for data management. And if their headcounts are low, these methods just might work.

But this type of system is not sustainable for long-term growth. Traditional EHS data management often stifles innovation, inhibits scalability, and complicates compliance. Luckily, the COVID-19 pandemic has served as a catalyst for the growth of cloud-based EHS compliance software.

With the power to analyze EHS data in real time, access it from anywhere within the organization, and collaborate across departments and site locations, EHS compliance is easier than ever.

Difficulty of implementation

A common concern about cloud-based software is the time investment to implement it. Many businesses feel that their traditional OSHA recordkeeping systems work well enough to hold off on upgrading to a cloud-based solution.

However, the process to develop and roll out EHS software varies drastically from business to business. Factors that affect the implementation timeline include:

- Size of organization

- Buildout of custom integrations and tools

- Communication between vendor and customer

- Training for how to use the new system

While some organizations might start using software within weeks of signing with a vendor, others might take several months.

You must consider long-term organizational goals when switching from paper to the cloud:

- Do you want to expand to multiple sites?

- Are your current systems difficult to teach to new employees?

- Can you depend on your current recordkeeping system when you need to access specific data, information, and records?

Ensuring the security of a physical document storage location is often more tedious than using a cloud system. Locks, cameras, and fire-proof storage containers are just some of the safeguards that businesses must implement. Without a standard way of storing and retrieving files, you may be in trouble the next time OSHA requests a specific record.

Software cost and upkeep

For many companies, the cost of software is a major concern. And when compared with the low cost of creating a compliance system in-house, cloud-based EHS software solutions may seem like an extravagant expense.

A driving factor behind this worry is simply the lack of price transparency from software providers. But there is a reason for this: cloud-based software solutions are often priced according to the needs of individual businesses.

This means that you can build a system specifically for your workforce. Whether that means you only need an LMS or you want action tracking capabilities as well, cloud-based solutions make it easy to scale or downsize.

The limitations of a traditional compliance approach

Creating comprehensive EHS management systems from scratch is extremely time-consuming. It also requires a fair amount of input. The systems that most businesses create in-house take years to develop and are difficult to teach to newcomers. This is especially the case when compliance trackers, file folders, and resources are stored in several locations.

And what happens when the person who created a mission-critical spreadsheet or document leaves the company? Oftentimes, turnover of safety team members means adjustments to the current system. It may also mean a tedious handover of documents that have become essential to OSHA reporting and compliance.

But remaining compliant should be a top priority, and your EHS reporting system should reflect your commitment. If you’re considering a cloud-based system, you need to think of it as a long-term investment in your business.

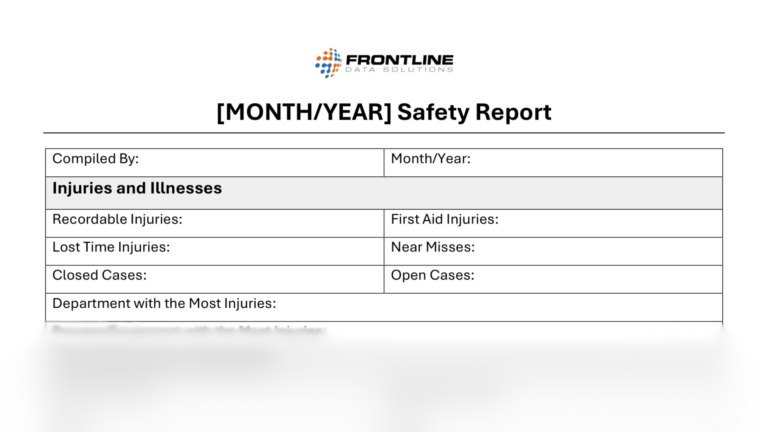

Free template!

Compile your monthly safety reports with this easy-to-use Word template.

The benefits of a cloud-based system

Accenture’s 2020 survey of more than 750 CEOs found that most leaders consider cloud solutions to be essential for reducing overall risk. And there are many reasons why. Cloud-based software is the future of EHS compliance because of its scalability, customizability, and reliability to businesses of all sizes.

Consistent format

OSHA compliance requires an organized document management system. EHS cloud-based software provides just that. Rather than using a variety of storage locations and types of files, a cloud system stores everything in a consistent format. This makes it easier to pull analytics and compliance reports that you can download and share with internal and external stakeholders.

Future scalability

Another major benefit of cloud-based solutions is their scalability. Say, for example, that you subscribe to an EHS software platform for one site within your company. Over time, you realize how effective the system is, and you decide to expand it to all your facilities.

Working with a software provider allows you to easily expand your system to new users. With a paper compliance system, you must figure out the complicated logistics of sharing new tools across sites and ensuring that they are implemented. With a cloud system, you gain access to important data like:

- Adoption rates of various tools and systems

- Compliance reports

- EHS analytics for individual sites and the entire organization

As your organization grows, these data points become more critical to safety performance oversight. And the benefit of the cloud is that you can access this information from anywhere if you have the correct permissions and login information.

Customized solutions

Depending on your EHS software provider, you can customize the set of tools, modules, and resources in your system. Your options may include custom:

- Workflows

- App integrations

- Compliance reports

- Employee training reports

- Organization-wide safety alerts

It’s important to note that not all providers are able or willing to make sweeping customizations. Most providers will offer an out-of-the-box system that requires further development if you want to personalize it. This extends the implementation process and increases the cost, so you should only ask for customizations that are mission-critical.

How to transition to EHS software

While most EHS professionals recognize the benefits of modern cloud-based software, many are reluctant to make the switch. Common concerns include:

- Investing time to research software solutions

- Teaching stakeholders how to use the software

- Moving critical data from one system to the other

- Ensuring widespread adoptions

- Coordinating software rollouts across multiple sites

- Buy-in of EHS professionals who prefer comfortable reporting methods

There’s also the difficulty of switching to cloud software when operations run non-stop. For many businesses, the logistics of launching a new cloud-based solution are enough to avoid it altogether.

But, once it has been implemented, EHS cloud data is undoubtedly more effective than the traditional approach.

Getting started

The simplest way to transition to a new EHS compliance software is to set a cut-off date after which all data (training, action items, MOCs, etc.) will be entered into the new system. Tasks in the old system will be closed out over time, allowing you to fully retire the legacy system.

The advantages to a fresh start are subtle but significant:

You leave behind any baggage associated with the old system (most notably redundant and/or disorganized data). And a clean break means that you can start up with the new system almost immediately.

The drawbacks are that you’ll need to keep the old system running while closing out tasks. In the meantime, historical data will continue to reside in the legacy system.

If you’re transitioning from paper files, this is almost always the best option. Scanning physical documents into a new software system is time-consuming. Plus, you’re likely to make errors. Even if you’re coming from an electronic system (spreadsheets, databases, or another software system), starting fresh may still be the best option.

Reevaluating the current system

Organizations often take the transition to modern EHS compliance software as an opportunity to re-examine and strengthen their existing procedures. These new, enhanced procedures may be too complex or simply incompatible with the legacy tools but are right at home with modern EHS compliance software.

When starting fresh, you can redesign your workflows, forms, categorizations, etc. around the more powerful options available in your new cloud-based system. You may even be able to collaborate with your software provider on a custom tool or integration.

Migrating data from your existing system

Businesses often want to avoid the time investment of setting up a new cloud based EHS compliance system. But having your data in one place is worth the effort and potential downsides of the migration process.

Think about how difficult and time-consuming it is to get safety professionals to use a new spreadsheet, app, or filing system. Doing this manually arguably requires much more time and energy than a widespread software implementation.

Consolidate your EHS data into a new cloud system by:

- Manually entering data

- Programmatically importing data

These two methods can be used side-by-side; however, they mainly depend on your cloud system’s capabilities. Before you sign up with a provider, make sure to ask how you can transfer data from your old system.

Manual data entry

If you’re coming from paper files, manual data entry is the only viable option. You’ll need to decide whether you want to enter all historical records or establish a cut-off date, such as the two most recent calendar years.

You’ll also need to decide whether it’s acceptable to enter summary data into the new system or if you’re willing to commit the time needed to add the full details of all historical records.

Programmatically importing data

It’s impractical to manually enter thousands or even millions of records, which is why you should look for an automated import solution.

Some providers can work with IT and EHS departments to map data from your legacy system into the new system. However, there may be slight differences that require human judgment and input.

For example, a priority level of “Urgent” might simply mean that an event needs to be labeled with the “High Priority” label. It might also mean that you need to upload the event into a different workflow altogether. This mapping process can take a few days up to a few weeks based on the complexity of your legacy data.

After the mapping of the legacy data to the new system is complete, software engineers may set up a quality assurance (QA) site where you can test the data import.

Once the imported data looks good, you can set up a cut-off date to transition from the legacy system to the new one. The full process can take as little as a week for simple data sets and up to a couple of months for more complex requirements.

Stepping into the future

Making the switch to a cloud based EHS compliance solution is an extensive process. It requires a thorough assessment of your current system—what works and what doesn’t. You can typically expect the implementation process to take a few weeks to a few months depending on whether you customize your system.

Both small and large businesses can benefit from the reliability and structure of cloud software. Its scalability and functionality make it a better option for EHS management than traditional methods. Paper documentation and file-based analytics limit your overall scope. They may cause you to miss out on key data points, trends, and patterns. EHS software takes you into the future of OSHA compliance by making it easier than ever to review site analytics and adjust accordingly.

The standardization that cloud-based solutions provide will allow you to track the progress of your safety initiatives efficiently. And when it comes to incident prevention, time is of the essence. An upgrade to cloud-based EHS compliance software will tip the scale for your organization, ensuring comprehensive oversight and optimizing your compliance approach for years to come.