The beauty of manufacturing process improvement is that there are so many different areas to tackle. From HR processes to equipment maintenance, you shouldn’t have much trouble finding improvement opportunities. But if you’re struggling to get started, maybe these project ideas will help give you some inspiration.

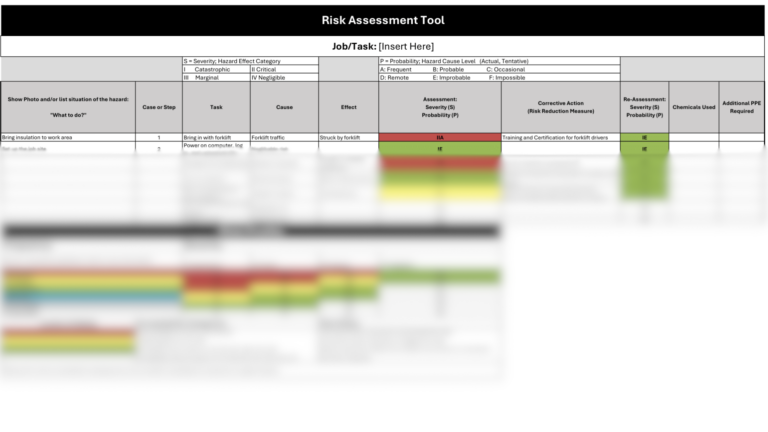

Free template!

Download this free Excel template to complete an extensive manufacturing risk assessment at your site, focusing on improvement areas related to the manufacturing process.

Equipment and tools

Most manufacturing processes involve heavy machinery like conveyor belts and reach trucks. But even in the offices, workers have radio, laptop computers, and other technology equipment that needs upkeep. So, the sheer amount of equipment in a manufacturing facility means there are endless opportunities for process improvement in this area.

Here are some equipment-related projects your team can tackle to contribute to process improvement:

- Red tagging and fixing broken equipment

- Purchasing and replacing equipment

- Storage and organization of process tools

- Preventative maintenance and equipment repair

Human resource management

Because people are unpredictable, the HR department is always a great place to find improvement opportunities. It’s also a good choice because human resources involves so many different processes that contribute to the overall manufacturing process improvement.

For instance, here are examples of HR-related projects you can do within your manufacturing facility to improve processes:

- Documenting and tracking HR investigations

- Collecting and importing employee data

- Organizing employee documents

- Tracking employee timecards, PTO, etc.

- Submitting payroll

Training and onboarding

Many companies overlook the importance of employee training and onboarding. It can be a major factor in the safety and overall performance of your manufacturing facility. Whether you hire contract employees or full-time workers, everyone needs access to quality information to facilitate process improvement.

Here are some manufacturing process improvements you can do for training and onboarding:

- Comprehension and retention of training material

- Incident rates for workers in their first month(s) of employment

- On-time completion of training requirements

- Quality and relevancy of training materials (videos, PowerPoints, tests, etc.)

Supply chain improvements

Depending on your business, you may manage a large and complex supply chain. Therefore, ask yourself, “Are we spending too much or waiting too long for any of the materials we need?” Effective supply chain management plays a critical role in improving manufacturing processes.

However, unlike other areas of process improvement, you might have limited control over certain aspects. This is because you may not be able to renegotiate supplier contracts or reconfigure your processes immediately. Nevertheless, keep these considerations in mind so that when your contracts expire, you are ready to secure better terms or switch suppliers to achieve greater efficiency.

- Lowering the cost of raw materials

- Adding new suppliers to the mix (diversify sources)

- Decreasing product lead time by reducing material sourcing times

- Streamlining the shipment of raw materials or components

Manufacturing processes

Of course, this list would not be complete without addressing the production process itself. After all, not all facilities operate the same way, so you should use this list as a starting point for evaluation. In addition, take time to consider your manufacturing goals, the products you currently produce, and where you can improve overall output.

Here are several manufacturing process improvement ideas you can explore:

- Decrease DPMO (defects per million opportunities)

- Increase process throughput

- Simplify process steps for each area of production

- Automate parts of the process that create bottlenecks

As you can see from this list, there really are countless ways to improve manufacturing processes. When it comes to implementing your improvements, EHS software is a powerful tool you can use to manage and oversee the process from start to finish.

Tracking process improvements with Frontline ACT

Frontline ACT is an EHS action tracking system that you can use for all types of workplace improvements, incidents, and more. It allows you to delegate action items to members of your operation and track their progress.

This saves you time by eliminating the administrative work of project management. But it also prevents projects from falling through the cracks and helps ensure efficiency. If you’re interested in learning more about Frontline ACT as a process improvement tool, book a demo with our sales team to explore ways to enhance the manufacturing process.