For an organization to have a robust safety program, it must have a strong commitment to safety. Thankfully, there are many things you can do to ensure your program’s success. Some of the manufacturing best practices that I’ll cover in this blog include:

- Preventing workplace injuries, illnesses, and deaths

- Preventing suffering and financial hardship for employees, their families, and employers

- Improvements in product and process quality

- Improved morale among employees

- Decreasing employee turnover

- A positive image and reputation among customers, suppliers, and the community

There are six key recommended elements of a successful EHS program. Together, these are the manufacturing best practices that you should implement. Let’s talk about each one down below.

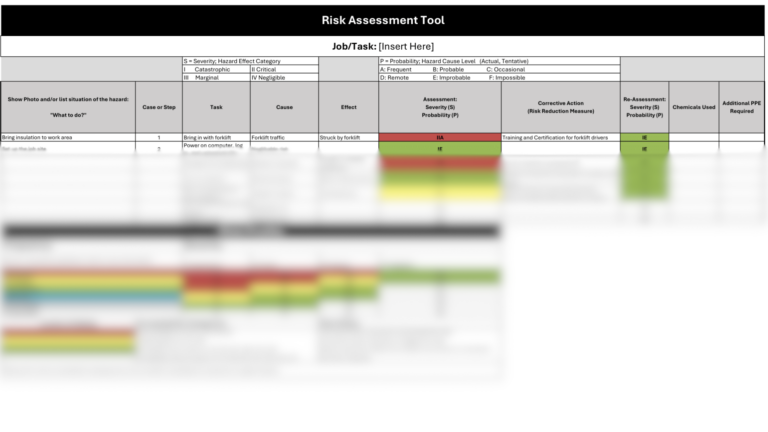

Free Template!

Use this Excel template to conduct a thorough manufacturing risk assessment of your processes.

Management Leadership

Management leadership creates the safety culture and facilitates trust in the organization. The management leadership element provides the vision and resources needed to implement an effective safety and health program. Business owners, managers, supervisors will:

- Make workplace safety and health a core organizational value

- Commit to reducing hazards, protecting workers, and continuously improving safety and health in the workplace

- Provide the resources to implement and maintain aspects of the safety and health program

- Visibility demonstrate and communicate their safety and health commitment to workers

- Set an example through their actions

Worker Participation

Worker participation is the next manufacturing best practice. It results in better design, implementation, and evaluation of the safety and health program. Therefore, to have an effective safety and health program, workers must actively participate.

Your employees know the most about the hazards they face. Successful workplaces will build an effective program with their worker’s knowledge and expertise. Workers should:

- Help establish, operate, evaluate, and improve the EHS program

- Participate and feel comfortable reporting health or safety concerns

- Have the opportunity to participate in all phases of the program design and implementation

- Not experience retaliation for expressing health and safety concerns, report injuries, or exercise any of their rights under the OSH Act

Hazard Identification and Assessment

Hazard identification and assessment is a critical element that identifies and documents all known and potential hazards. After an injury occurs, a probable root cause is the failure to identify or recognize hazards. An adequate safety and health program will have a robust process to identify anticipated hazards. To identify and assess hazards, employers and workers must:

- Collect and review information about the possible hazards in the workplace

- Conduct periodic workplace inspections to identify new or frequent hazards

- Investigate injuries, illnesses, and near misses to determine the underlying hazards, their causes, and the safety and health program weaknesses

- Identify trends by similar grouping incidents, injuries, illnesses, or near misses reported

- Consider hazards associated with emergency or non-routine situations

- Determine the severity and likelihood of each hazard identified, and use this data to prioritize corrective actions

Hazard Prevention and Control

The hazard prevention and control element prevents injuries using the hierarchy of controls. Elimination or Substitution is the most effective control, followed by engineering controls, then administrative controls, and the least effective control is the use of PPE.

Having effective controls protects workers from workplace hazards, preventing injuries, illnesses, and near misses, minimizing or eliminating risk, and providing the worker with a safe workplace. After hazards are identified and assessed, an organization must control the hazards. To successfully manage and prevent hazards, employers should:

- Involve workers in how they think hazards should be controlled

- Identify and assess options for controlling hazards using the hierarchy of controls

- Use a hazard and control plan to guide the selection and implementation of controls

- Develop policies with measures to protect workers during emergencies and non-routine activities

- Evaluate the effectiveness of the implemented controls to determine if they continuously protect from hazards

This manufacturing best practice is preventative, and it’s essential for a well-rounded EHS program.

Manufacturing Education and Training Best Practices

The education and training element ensures that all workers understand the hazards they face while on the job, safe work practices to prevent injuries, and recognize how to participate in a safety and health program.

Providing training and education are essential tools for informing workers and managers about workplace hazards and controls to ensure they can work more safely and be more productive. It will also provide workers with a better understanding of the safety and health program to participate in its development and implementation.

Education and training provides business owners, managers, supervisors, and workers with:

- Knowledge and competences needed to work safely and to avoid creating new hazards

- Understanding of hazards and how to identify, report, and control them

- Specialized training when the work involves distinctive hazards

Effective training and education can be provided by classroom discussions, peer-to-peer training, on-the-job training, or demonstrations.

Program Evaluation and Improvement

Program evaluation and improvement determines program effectiveness and whether you need to make modifications. Once you create your EHS program, you must perform and evaluation to determine its effectiveness. Periodically and at least annually, assess the program to determine what is and is not working and if it is on track to achieve its goals.

If you find opportunities to improve the program, all employees (supervisors, managers, and employees) should make corrections and monitor how well the program performs. Sharing the monitoring results and the evaluation in the workplace and celebrating success will help drive further improvement within the organization.

Program evaluation and improvement includes:

- Establishing, reporting, and tracking goals, objectives, and targets that determine if the program is making progress

- Evaluating the program initially, then periodically to determine weaknesses and opportunities for improvement

- Offering ways for workers to participate in program evaluation and improvement

If you follow these manufacturing best practices, you’ll reduce risk, improve engagement, and boost efficiency across your business.