Can you recall a time when someone asked you not to do something, but you did it anyway? In the workplace, safety depends on making conscious decisions that protect both you and your surroundings. However, certain behaviors can undermine that safety. This is where behavior-based safety (BBS) comes into play. Safety pioneer Herbert William Heinrich likely introduced BBS in the 1930s to address these behavior-driven risks.

What is behavior-based safety?

Behavior-based safety (BBS) is an approach to improving performance and reducing the frequency of accidents and injuries. The process identifies the causes of unsafe behaviors and eliminates them through training, coaching, positive feedback, and recognition. Simply put, BBS attempts to “change the way people work,” much like other approaches such as layered process audits, 5s audits, or Kaizen events. But BBS also adds a component that some of these other approaches don’t have. It addresses what we can refer to as the “softer” side of existing practices — specifically employee conduct, attitude, and collaboration.

How do we define unsafe behavior?

88% of workplace safety incidents are the result of unsafe behaviors, which is why BBS is considered significant. So, what is this so-called “unsafe behavior?” Unsafe behavior is conducting an action that may increase the probability of an injury or incident. Some of the most common unsafe behaviors in the workplace are;

- Improper use of PPE

- Failure to use PPE

- Use of defective equipment

- Removal, or failure to use, of safety devices

- Operation of equipment at unsafe speeds

- Operation of equipment without proper authorization, training, and/or qualifications

These acts are all considered to be a “human error.” However, human error cannot always be the root cause of why an incident occurred. It is more likely to be a causal factor. Experts categorize human error into two parts: errors and violations. Errors consist of unintentional and habitual actions, while violations involve conscious behaviors.

Everyone makes unintentional errors. When you come across someone making an unconscious mistake that creates risk, make sure to draw attention to what they are doing. Habitual mistakes might have multiple reasons for occurring. An employee might not have clearly understood a certain process. Alternatively, they might not be aware of a rule or regulation that recently changed. It’s important to understand the reason behind this habit and address it accordingly.

How to implement behavior-based safety?

The key to successfully implementing a behavior-based safety (BBS) program is recognizing that it must be inclusive and collaborative. Safety leaders should make it clear that reducing workplace risks and injuries is only possible with the active support and involvement of employees. Promoting BBS as a shared responsibility—not just a set of rules—helps foster a culture where safety becomes part of everyday behavior.

Listen

To succeed, BBS requires strong top-down engagement. When workers see upper management actively participating in safety efforts, they are more likely to follow suit. For example, when an employee notices unsafe behavior and reports it to their supervisor, leadership must respond supportively. Listening to workers and encouraging open communication ensures they feel empowered to speak up about potential hazards without fear of judgment.

Observe

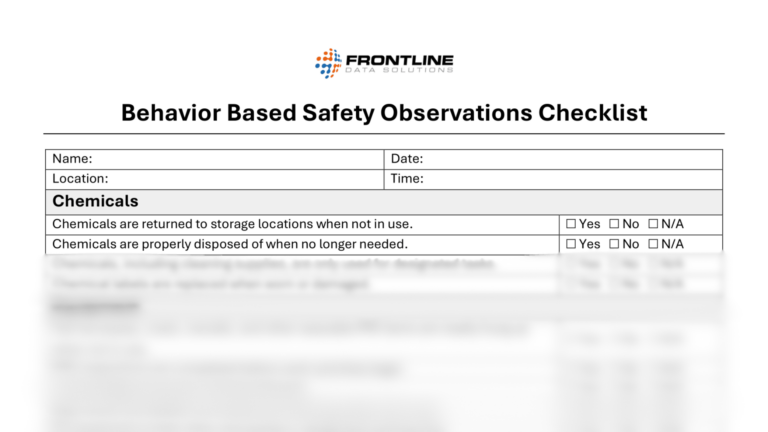

Observation plays a central role in identifying unsafe behaviors and addressing safety issues before they lead to incidents. Depending on the work environment, observation should cover areas such as PPE usage, procedural compliance, chemical handling, fall protection, and ergonomics. Using a BBS observation checklist or action tracking software can help you monitor these behaviors consistently and gain full visibility across your workplace.

Give feedback

Pointing out mistakes and wrongdoings is not going to help create an environment where workers feel comfortable enough to share their observations and take part in BBS. Providing positive reinforcement is also difficult to sustain. It might not always bring results when implemented towards adults. This is why it’s important to make frequent observations and give feedback on what the observation entails.