An arc flash occurs when a flashover of electric current leaves its intended path and travels through the air from one conductor to another, or to the ground. Conducting an arc flash risk assessment is crucial to prevent such dangerous incidents.

The hazards resulting from an arc flash incident include burns, extreme heat and fire, flying objects, molten metal, and blast pressure or sound blast. Arc flashes are often violent, and when a human is near the arc flash, serious injury or even death may occur.

In this post, I’ll share some of the information you’ll need to complete an on-site arc flash risk assessment.

The Severity of an Arc Flash Injury

There are many things that can cause arc flashes, including:

- Dust

- Dropping tools

- Accidental contact with particular parts

- Condensation

- Material failure

- Corrosion

- Faulty installation

Three factors determine the severity of an arc flash injury: proximity of the worker to the hazard, temperature, and the time it takes for the circuit to break.

Because of the violent nature of an arc flash exposure, employee injuries can be very serious. It’s not uncommon for an injured employee to never regain their previous quality of life and they may also require extended medical care.

Approach/Protection Boundaries

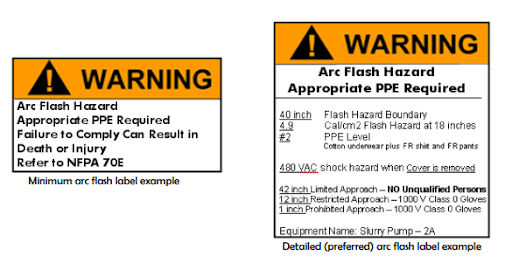

The National Fire Protection Association (NFPA) developed specific approach boundaries designed to protect employees working on or near energized equipment. It’s crucial to understand boundary locations before beginning work on equipment, as these define the employees’ potential exposure to an arc flash and the severity of hazards. Therefore, boundaries play a massive role in determining the amount of risk that employees face when conducting their work.

These boundaries, listed from outermost to innermost, include flash protection, limited approach, restricted approach, and prohibited approach. The risk from exposed live parts depends on your distance from those parts.

Exposed electrical components pose a hazard, and workers can get shocked if they touch wires, terminals, or other parts.

Flash Protection (Outer Boundary)

The flash boundary marks the farthest distance from the energy source where arc flash protection is required. If an arc flash occurs, this boundary is where an employee would suffer heat exposure. This exposure may cause curable second-degree burns (1.2 calories/cm2). The heat generated from a flash creates the primary hazard within this boundary.

Limited Approach

An approach limit at a distance from an exposed live part where a shock hazard exists. The limited approach is the closest an unqualified person can approach, only allowed further if a qualified person accompanies them. A qualified person has received training on the potential hazards and the construction and operation of the equipment involved in a task.

Additional requirements for qualified persons include the skills and techniques necessary to distinguish exposed live parts from other parts of electrical equipment and being able to determine the nominal voltage of exposed live parts. Working on equipment without proper qualification and training severely increases risk.

Restricted Approach

The limited approach boundary is a specified distance from an exposed live part where a shock hazard exists. The restricted approach is the closest to the exposed live parts that a qualified person can go without proper PPE (such as flame-resistant clothing) and insulated tools.

When the employee is at the restricted approach boundary, the employee or their tools could touch live parts if the employee is careless with their movements.

Prohibited Approach (Inner Boundary)

Treat any distance from an exposed part that allows electrical conduction as equivalent to making direct contact with the live part. The prohibited approach is the distance that the employee must remain from exposed live parts in order to prevent flashover or arcing in the air.

Note: These distances are not the same for all types of equipment. Some equipment will have a larger flash protection boundary, while others will have a smaller boundary. Refer to NFPA 70E for boundary distances at given voltage ranges.

Safety Around Electrical Hazards

To be safe, employees must think about the job and plan controls for possible hazards. The three-step model to follow for optimum safety practices around electrical hazards is recognizing, evaluating, and controlling the hazards.

To avoid injury, the employee must understand and recognize hazards and evaluate the situation by assessing the risks.

Remember: The most effective way to eliminate the risk of electrical shock or arc flash is to de-energize the equipment and not work on equipment that is “live.”

Examples of how the three-step model can protect against electrical hazard risk and arc flash require planning and establishing proper controls. Controls to prevent injury include:

- De-energizing, locking, and tagging out circuits and equipment, and not working “live” whenever possible.

- Using proper insulation, guarding, and grounding (including ground fault circuit interrupters (GFCIs)).

- Barricades to warn others of the boundaries.

- Preventing system overloads.

- Reading all arc flash labels to determine the level of PPE required and boundary distances.

Other Risk Assessment Considerations

What makes arc flashes such a common hazard is just how many variables contribute to them. Below are some additional precautions you can take to reduce arc flash risks in your worksite.

Grounding

Ground all metal parts of electrical wiring systems that people can touch to maintain them at 0 volts. If you don’t ground electrical systems, the metal parts of equipment can become energized.

A missing ground creates a hazard by preventing the safe elimination of unwanted voltage. When nonconductive material blocks the path to ground, it can cause electric shocks and potential arcing. To minimize the chances of improper grounding, check power tools and outlets before use to make sure they contain a GFCI device. A GFCI will reduce the risk of current leakage.

Overload Hazards

Overloads in an electrical system can produce heat or an arc. Additionally, wires and other components in a system or circuit have a maximum amount of current that they can carry safely.

If you plug too many devices into a circuit, the electrical current will heat the wires to a very high temperature. This may cause the wires to heat up enough to cause a fire.

If the insulation melts, arcing may occur. Arcing can cause a fire in the area where the overload exists, even inside a wall. To reduce the risk of overloading, check that the associated circuit breakers and fuses are working correctly.

PPE

Conduct a risk assessment for every piece of equipment operating at 50 volts or more if you do not de-energize it. Your evaluation should determine the required boundaries and PPE.

Employees must follow the PPE requirements established on arc flash labels. Remember, PPE does not eliminate the electrical hazard or arc flash risk. However, it can help to reduce the severity of an injury.

Why Arc Flash Risk Assessments Matter

Conducting a thorough arc flash risk assessment is not just a regulatory checkbox, it’s a critical safeguard for your team’s safety and your facility’s operational continuity. By identifying potential hazards, calculating incident energy levels, and implementing appropriate protective measures, you can prevent serious injuries and costly downtime. Investing in a professional arc flash risk assessment today helps ensure a safer, more compliant workplace tomorrow.