Personal protective equipment is the last level of protection in the fight against safety hazards. Even still, you need to supply adequate PPE to your workers which is a requirement under the OSHA standards for PPE. As always, consult with these standards to determine the best way to protect your team. Personal protective equipment is the level of protection that creates a safety buffer against hazards.

Free checklist!

Use this checklist to inspect all your site’s PPE and ensure it meets the requirements of your EHS program, confirming that personal protective equipment is the level of protection applied correctly.

What are the different personal protective equipment level of protection?

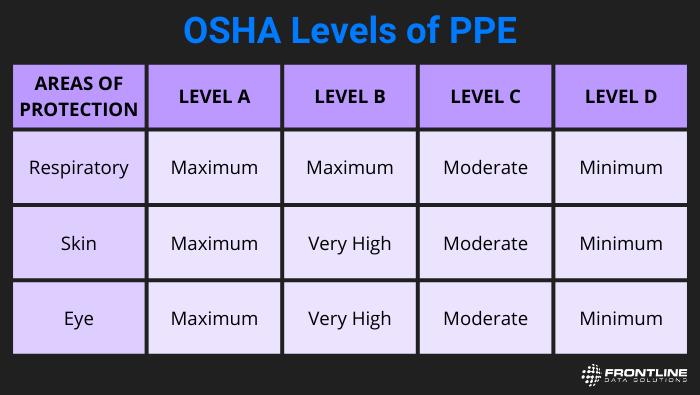

There are four different levels of PPE which are ranked in order of severity from highest to lowest. You can find an in-depth description of each level in OSHA standard 1910.120 Appendix B, “General Description and Discussion of the Levels of Protection and Protective Gear.”

Here is a brief overview of each level and what it requires:

Level A

At this level, there’s a high risk of skin, respiratory, and eye injury without PPE. Some examples of level A equipment include chemical-resistant materials, steel toe boots, and full body chemical suits. Personal protective gear at this level of protection is essential when these risk factors are present.

You should use level A PPE when you’ve identified a specific hazardous substance or an unknown, potentially hazardous substance. And you should also use it when your processes create a higher risk of injury. For example, if you’re a chemical manufacturer, your employees might get splashed with dangerous substances. So, they need clothing that shields their skin from contact with those materials.

Level B

At this level, workers still face a high risk of respiratory injury but a lower threat of skin exposure. Therefore, it’s important to provide NIOSH-approved respirators and chemical-resistant clothing to maintain safety.

In addition, if employees work in poorly ventilated spaces where they might inhale harmful substances but are unlikely to experience direct skin contact, level B PPE is the appropriate choice. Finally, always remember that wearing personal protective equipment is essential for managing both known and potential hazards effectively.

Level C

At this level, the threat of unknown airborne substances or chemicals remains moderate. Therefore, you can still consider using some of the equipment from categories A and B, but it’s usually unnecessary because the overall risk is lower.

In addition, when the work area provides proper ventilation and eliminates direct skin contact with identified substances, level C PPE becomes appropriate. This ensures that personal protective equipment continues to meet the required level of protection for the task.

Level D

At this level, there are no known or suspected hazards, so most forms of PPE are optional. Thus, you may still choose to use protective gear for certain processes, but it’s not necessary.

When should you modify your personal protective equipment level of protection requirements?

Using level C or D equipment depends on being able to know and control the risks you identify. That means that if you detect a new respiratory hazard, you should upgrade to a more comprehensive PPE option.

It may also be necessary to upgrade to a higher PPE level when you change your work processes. If a change to one task puts workers at risk of skin contact with harmful materials, they’ll need the proper clothing to protect against those substances.

These principles go in the opposite direction too. While monitoring your worksite, you may realize that a hazardous substance is less dangerous than you initially thought. Or maybe you implement a process improvement that lowers the amount of contact workers have with a skin hazard. In both cases, you can consider downgrading from level A or B gear. Adjustments to levels of protection with personal protective equipment should align with current assessments.

Continued personal protective equipment level of protection guideline compliance

At this stage, complying with OSHA’s PPE standard requires continuous monitoring of workplace conditions. Therefore, as operational variables shift, the PPE requirements for each protection level may also change. In those cases, you must adjust your site’s PPE program to stay compliant and ensure worker safety.

Ultimately, remember that personal protective equipment serves as the final line of defense against the hazards your workers face each day. When making complicated changes to processes, equipment, and people, follow the change management process. And during this process, if you create or uncover a new health hazard, reevaluate your PPE requirements and adjust them quickly to avoid costly incidents down the line.