One of the best ways to protect yourself against workplace safety hazards is to stay out of the line of fire. This means you need to understand the different sources of risk in your work area and how to control them. Recognizing and controlling line of fire hazards is one of the most important aspects of personal safety that everyone—regardless of where they work—should know.

What is line of fire safety?

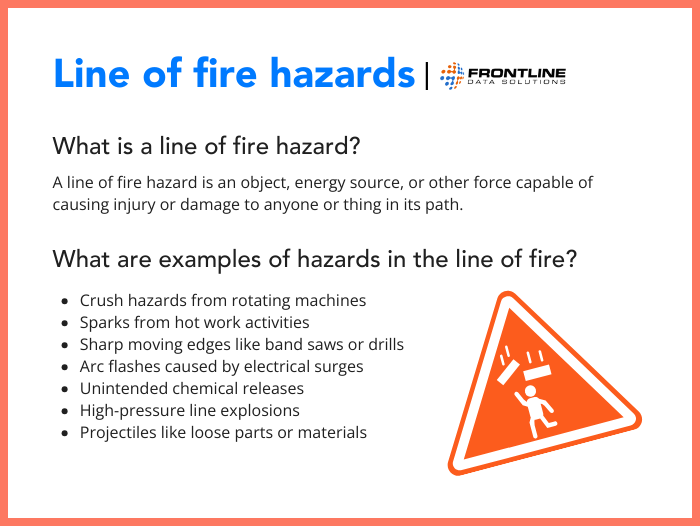

The line of fire refers to any area where workers are at risk of injury if they’re in the way of a hazard. The hazard could be an object, energy source, or any other force capable of causing damage. Therefore, understanding these line of fire hazards is essential.

Typically, you’ll come across more of these hazards in industrial settings than in an office, for example. And that’s because of all the machinery, equipment, tools, energy sources, and other variables that exist. In these environments, line of fire hazards are plentiful.

Even so, every work area has its own risks that you should account for. Being aware of your surroundings is essential for maintaining personal safety, but it’s also necessary to keep others safe as well. Awareness helps in identifying line of fire hazards.

Line of fire hazard examples

To keep yourself and others safe at work, you must first know the safety risks in your area. Here are some examples of line of fire hazards that you might come across. Recognizing these hazards is crucial.

Powered tools and equipment

Powered equipment puts you in the line of fire because of what can happen if you use it improperly or lose control. Plus, the equipment itself may be dangerous even if it’s not turned on. Consider these examples of line of fire hazards:

- Sparks from welding, cutting, or soldering tools

- Hot molten metal from processes involving fire

- Sharp edge hazards (e.g., saws, drills, knives, etc.)

- Crush hazards from heavy or rotating machines (e.g., conveyor belts, presses, etc.)

Energy sources

Powerful energy sources, and the failure to control them, create a lot of hazards. You might be standing close to one of these sources, seemingly out of harm’s way, but still be in danger if you’re not careful. Some examples of conditions that would put you in the line of fire include high-pressure line of fire hazards.

- High-pressure line accidentally releases or explodes

- Electrical surge causes an arc flash

- Adverse chemical reaction causes an unintended release

- Excessive force creates projectile hazards (e.g., loose parts, materials, etc.)

Operator failures

Like equipment poses risks on its own, so do the human operators of that equipment. When you’re interacting with others in the workplace, you’re in the line of fire of their use and misuse of machinery. Here are some examples of hazards that come from operator failures, including line of fire incidents:

- Traffic accidents or PIT-pedestrian collisions

- Uncontrolled equipment (e.g., floor buffer or jackhammer set loose on accident)

- Energized equipment that’s not locked out correctly

- Falling objects that have been knocked over or dropped

- Hoisted load swinging uncontrollably

Notice that these hazards all stem from an unexpected outcome. No one expects, for example, a forklift boom to come swinging at them, but that doesn’t mean it can’t happen. Protecting yourself against these hazards depends on recognizing when you’re in the line of fire and figuring out how to get out of it safely.

Free form!

Download this free good catch report form to document all the issues your team finds and fixes. This can help with identifying potential line of fire hazards.

Ways to control these hazards

The best way to control line of fire hazards is to maintain constant awareness. This is easiest to achieve with proper training and concept reinforcement. Everyone at your site should be trained to identify line of fire hazards and know how to report them.

Outside of training, here are some other ways you can keep workers out of the line of fire:

- Require permits for hazardous work areas (hot work, confined space, etc.).

- Perform routine risk assessments to identify hazards.

- Enforce a strict lockout tagout process for energized equipment.

- Install machine guarding on all machinery, especially if it has moving parts.

Many of these strategies are outlined in OSHA’s process safety standard. The idea is that it’s better to remove hazards than it is to try and control them. But since you can’t remove the inherent dangers of hazardous chemicals and equipment, you must find ways to prevent misuse. By implementing these safety measures and enforcing them, you can better keep workers out of the line of fire and reduce the likelihood of incidents.