Hand safety tips are crucial to reducing workplace accidents. According to the Bureau of Labor Statistics, there were 102,350 nonfatal workplace hand injuries in 2020. That equated to 8.7% of all the total nonfatal injuries recorded within the private sector during that time.

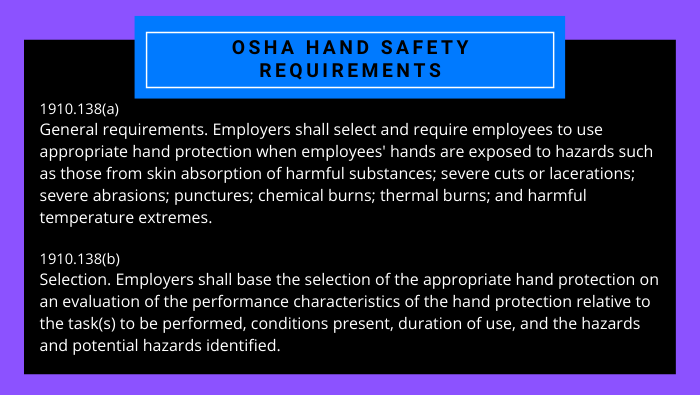

OSHA’s PPE standard sets clear requirements for adequate hand protection. Employers require workers to wear protective gloves when they face hazards such as harmful substances or sharp surfaces. They also choose PPE specific to each task and work condition to give workers the best possible protection for their hands.

Overall, these regulations are relatively straightforward and open to each site’s discretion. But aside from simply using the right PPE, you should also develop habits that offer practical tips for hand safety to protect your hands.

If you need some inspiration, here are 20 useful tips on hand safety to share with your team and coworkers to keep safety front of mind.

Clothing and hygiene

- Keep nails trimmed to no more than a quarter inch long.

- Wear sleeves that stop at the wrist area, avoiding oversized shirts with sleeves that can pull hands into unwanted areas. This is just the beginning of useful safety tips for hands.

- Choose gloves that fit correctly and have the necessary features (grip, chemical resistance, etc.).

- Take off accessories like rings, bracelets, and watches before starting work tasks.

- Replace PPE when it becomes worn out, and do not reuse single-use PPE over multiple shifts.

Hand Safety Tip Behaviors

- These vital safety tips for hands include always cutting away from the body, including hands.

- Keep hands and fingers clear of any moving machinery parts.

- Double check that the lockout tagout process has been followed before using any piece of energized machinery.

- Only place hands in designated areas, avoiding unknown spaces or areas where it’s difficult to see.

- When lifting objects, make sure to form a C-grip and use both hands when appropriate.

- Rotate hands and arms accordingly without twisting into uncomfortable positions is an important hand safety tip.

- Perform hand stretches before, during, and after each shift to ensure dexterity and prevent repetitive strain injuries.

- Before activating high-powered machinery, check to make sure the surrounding area is clear of electrical hazards, other workers, etc.

- Instead of using hands to load materials into machines, use reach tools instead for effective safety of hands.

Tools and equipment

- Check to make sure that all emergency stops are accessible and functioning before starting work.

- Never use equipment that is damaged or broken.

- Always use tools that match your hand size and dominant orientation (right or left). Therefore, never ignore these tips for hand safety.

- Audit the work area to double check that machine guards are placed in the correct position and are secured.

- Perform regular preventative maintenance on everything from conveyor belts to hand tools related to keeping hands safe.

- When not in use, store tools so they don’t create a hazard and/or interfere with the workspace.

If you liked these tips for hand safety, you might like our warehouse safety tips post or fire safety tips as well.