Facilities must follow applicable local, state, and federal standards and regulations regarding environmental compliance. Utilizing an environmental compliance audit checklist can help ensure adherence to these regulations. The Environmental Protection Agency (EPA) regulates environmental compliance by monitoring and performing inspections.

To be prepared for the EPA, employers should understand what environmental regulations are applicable and what type of records the EPA will look for if they perform an inspection.

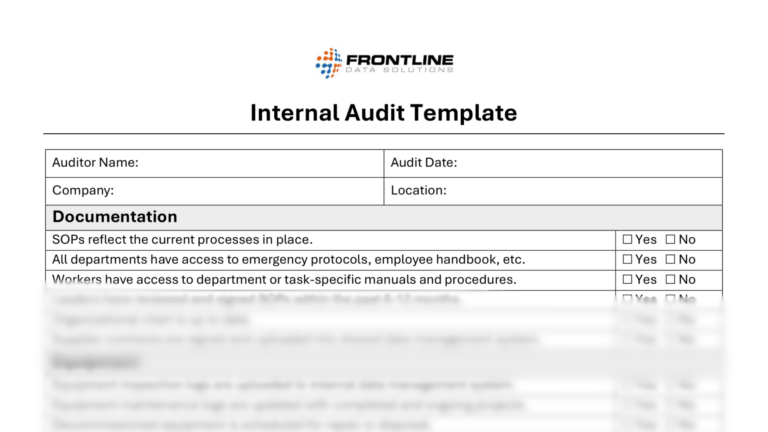

Free template!

Use this simple internal audit template to create a site-specific document for tracking your regulatory compliance.

How are environmental regulations enforced?

Below are the primary ways that regulatory agencies enforce environmental requirements in the United States.

Compliance monitoring

Compliance monitoring is one of the critical components the EPA uses to ensure that employers obey environmental laws and regulations. It encompasses all regulatory agency activities performed to determine whether facilities or groups of facilities comply with applicable laws.

In general, compliance monitoring includes:

- Formulation and implementation of compliance monitoring strategies

- Onsite compliance monitoring: inspections, evaluations, and investigations, including review of permits, data, and other documentation.

- Offsite compliance monitoring: data collection, review, reporting, program coordination, oversight, and support

- Inspector training, credentialing, and support

Inspections

Inspections are an integral part of the EPA’s compliance monitoring programs. They are an essential tool for officially assessing compliance with environmental regulations and requirements. The EPA and its regulatory partners conduct compliance inspections under the majority of statutory and regulatory program authorities.

Inspections are visits to a facility or site to gather information to determine whether the facility complies with local, state, or federal laws. Inspections generally include pre-inspection activities such as obtaining general site information before entering the facility or site. Other activities that may be conducted during the onsite visit include:

- interviewing facility or site representatives

- reviewing records and reports

- taking photographs

- collecting samples

- observing facility or site operations

Inspections are usually conducted by focusing on a single program, such as the Clean Air Act (CAA), but can be conducted for more than one media program. Inspections can also be conducted to address a specific environmental problem specific to a facility or industry sector. For example, CAA evaluations can be either a Full Compliance Evaluation (FCE) or a Partial Compliance Evaluation (PCE).

An FCE is a comprehensive evaluation of the facility’s compliance status and looks for all regulated pollutants at all regulated emission units. An FCE may be accomplished through a series of PCEs, which focus on a subset of pollutants, requirements, or emission units.

Environmental compliance audit checklist

How can companies make sure that their processes are complying and meet inspection guidelines? One way is to perform regular audits and record reviews of the facility that focus on the environmental regulations applicable to that facility. Employers should use the information below as guidance to prepare for an EPA inspection by ensuring records are documented, and facility inspections are performed.

Detailed regulatory checklists for compliance include the:

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

- Clean Water Act (CWA)

- Emergency Planning and Community Right-to-Know Act (EPCRA)

- Resource Conservation and Recovery Act (RCRA)

- Safe Drinking Water Act (SDWA)

- Toxic Substances Control Act (TSCA).

Some or all of these checklists could apply to a given facility or group of facilities.

CERCLA

Typical records to review:

- Spill/release records

- Hazardous substance inventory records

- National Response Center Notification Document

- Preliminary Assessment

- Remedial Investigation documentation

- Soil sample and groundwater monitoring data related to areas targeted for removal and cleanup

- Engineering and cost evaluations

- Sampling and analysis plans

Typical physical features to inspect:

- Cleanup sites

- Disposal sites

- Groundwater monitoring wells

- Contaminated areas

- Treatment technologies employed for site cleanup

CWA

Typical records to review:

- National Pollutant Discharge Elimination System (NPDES) Permits and applications

- Discharge monitoring reports for the past year

- Laboratory records, procedures, and EPA results

- Special reports and certifications required by a NPDES permit

- Notification to local Publicly Owned Treatment Works (POTW)

- Old spill reports

- Pretreatment permits

Typical physical features to inspect:

- Discharge to POTW

- Wastewater generation points

- Wastewater treatment and industrial treatment facilities

EPCRA

Typical records to review:

- Emergency response plan(s)

- Emergency Release Notification Reports

- Chemical inventory forms

- Safety Data Sheets (SDS)

- Tier I/Tier II reports

- Toxic Release Inventory (TRI) reports (Form R/Form A) and related documentation

- Hazardous communication plan

Typical physical features to inspect:

- Chemical storage, manufacturing, and processing areas

- Recordkeeping system

- Shop activities

- Hazardous material/waste transfer areas

- Treatment units

- Recycling sites

- Disposal sites

RCRA

Typical records to review in the environmental compliance audit checklist:

- Hazardous substance spill control and contingency plan

- Land disposal restriction certifications

- Emergency plan documents

- Placarding of hazardous waste and materials

- Treatment, storage, and disposal facility (TSDF) locations

- TSDF audit reports (inspection log)

- Employee training documentation

- Spill records

Typical physical features to inspect:

- Disposal sites

- Incinerators

- Container and bulk tank storage areas and containment buildings

- Site security measures such as door locks and fencing

- Posted signs

SDWA

Typical records to review:

- Bacterial and chemical analyses of drinking water, including sampling dates and locations, dates of analyses, analytical methods used, and results of analyses

- Monthly operating reports

- State and public notification of noncompliance with primary drinking water regulations

- Sanitary surveys of the water system

- Actions taken to correct violations of primary drinking water regulations

- Formal or informal enforcement actions issued by the state or EPA

Typical physical features to inspect:

- Laboratory analysis facilities

- Drinking water treatment facility and storage facilities

- Locations where additional treatment occurs, such as re-chlorination

- Potable wells

- Surface water intakes

TSCA

Typical records to review:

- Inspection, storage, maintenance, and disposal records for Polychlorinated Biphenyls (PCBs) items

- PCB equipment inventory and sampling results

- Manifests and Certificates of Disposal (CODs)

- Correspondence with regulatory agencies concerning noncompliance situations

- Annual reports

- Asbestos management plan and operating plan

- Notification to regulators concerning asbestos disposal

- Records of onsite disposal and transportation and offsite disposal of asbestos

- Regulatory inspection reports

- Documentation of asbestos sampling and analytical results

- Documentation of preventative measures or action

- Results of air sampling after response action

- Records of an asbestos training program

- List of buildings insulated with asbestos or housing asbestos-containing material (ACM)

- Record of demolition or renovation projects in the past five years involving friable asbestos

- Decision records/documents

- Facility Master Plan Document

- Spill Prevention Control and Countermeasure (SPCC) Plan

Typical physical features to inspect:

- PCB storage areas

- Equipment, fluids, and other items used or stored at the facility containing PCBs

- Pipe, spray-on, duct, and troweled cementitious insulation and boiler lagging

- Ceiling and floor tiles