ATP testing is critical for food manufacturers working to prevent food recalls and foodborne illnesses. By using this method, companies can verify facility cleanliness and protect product safety. For instance, the baby formula shortage that struck the U.S. in February 2022—and lasted for months—underscored the deadly risk posed by bacteria like Cronobacter sakazakii.

That’s why it’s important to implement ATP testing in your facility. ATP or adenosine triphosphate is a molecule found in all living or once-living cells. Even if you have cleaned and sanitized your work area or production facility, can you be sure that a visual inspection is enough?

What is ATP testing?

ATP is a vital molecule found in all living cells, produced through chemical reactions where ADP molecules combine with phosphate ions. This process forms ATP, which stores energy needed for essential cellular functions such as muscle contraction and respiration.

ATP testing measures the amount of ATP present on a surface or product. A low Relative Light Unit (RLU) reading indicates few or no living microorganisms in the tested area. In addition to detecting microbial contamination, ATP testing also identifies food residues—an important concern, as these residues can promote the growth of surviving organisms and increase the risk of contamination.

ATP testing is performed using a device called an ATP meter or handheld ATP tester. The meter shines a light onto the surface of a product and measures the amount of light reflected back. A higher-than-expected reading indicates the presence of bacteria, signaling that the product or surface requires additional cleaning.

It’s important to note that during the baby formula shortage referenced earlier, pathogens were reportedly found on non-food-contact surfaces—while Zones 1 and 2 remained clear. This highlights a critical point: even microorganisms on non-food-contact surfaces can contribute to foodborne illnesses and should be routinely tested.

Benefits of ATP testing

ATP testing is also used for pharmaceuticals, cosmetics, medical devices, and other products that come into contact with humans. Using ATP testing in your facility can have many benefits. The most important ones are ensuring that your facility and food are sanitary, and making sure your brand image is protected by providing quality products.

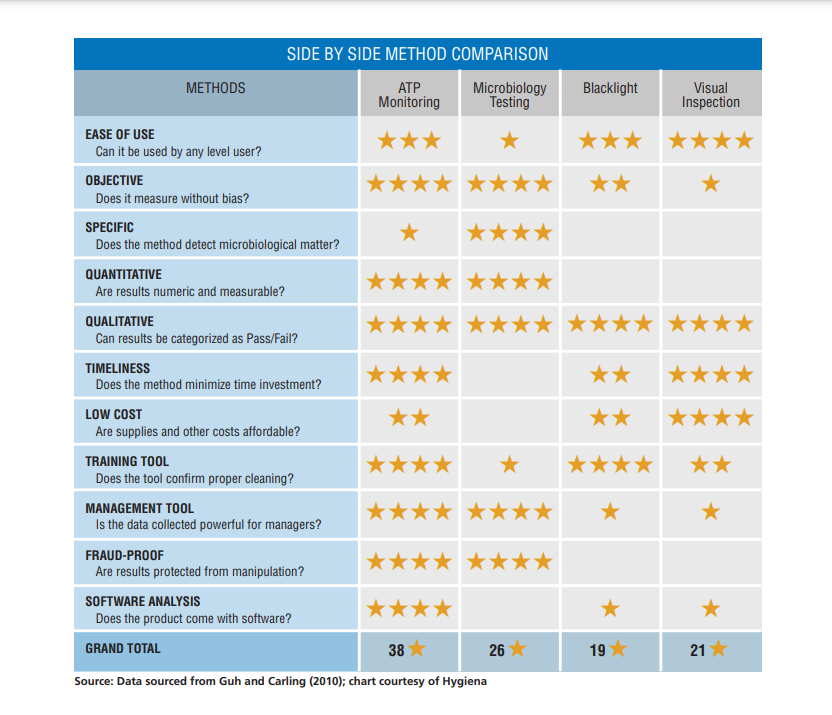

Here’s a comparison of ATP testing versus other methods that you might consider:

Ensuring food safety

The biggest benefit of the test is that it gives immediate results. This means you can quickly take corrective action and optimize your cleaning frequency according to the test results. By doing so, you can reduce reliance on harsh sanitation chemicals and cut down on labor-intensive cleaning tasks. Ultimately, ATP testing helps ensure food safety while saving time, reducing costs, and minimizing the risk of delayed production or product recalls.

Protecting your brand

A foodborne illness linked to your product can have devastating consequences for both your business and your customers. ATP testing helps prevent these incidents by keeping your products safe and your facility audit-ready. Facilities that consistently use ATP testing are more likely to perform well during inspections and avoid costly violations. As a result, you strengthen trust with clients, regulators, and third-party partners—ultimately reinforcing your reputation across the industry.