CASE STUDY

How Optec LED Lighting Streamlines Operations and ISO Compliance Using Frontline

Discover how the lean operations team at Optec LED Lighting created streamlined quality workflows and positioned for ISO 9001 certification—all without IT involvement.

Meet Optec LED Lighting

Wisconsin-based Optec LED Lighting is a leading manufacturer of high-performance exterior LED luminaires used in industries such airports, universities, restaurants, car dealerships, hotels, municipalities, and parking structures.

As a newly incorporated branch of legacy company, Optec Displays, Inc. Optec LED Lighting focuses on delivering quality LED solutions while building robust operation processes to support scale, compliance, and customer satisfaction.

Industry: Manufacturing

Company Size: 20 employees

Challenges: The newly-established operation lacked formal workflows outside of its ERP system, had limited visibility, and a manual quality tracking system.

Solutions: Frontline ACT

The Challenge: Set Up Lean Operational Processes to Support Growth

Optec LED Lighting faced significant challenges to start up a manufacturing operation during the pandemic. They needed to quickly create and introduce a formal quality management system (QMS), process management workflows, and structured communication with a small, overloaded team. Some of the initial challenges they faced were:

- Manual task tracking via Excel and email threads

- No formalized systems for engineering requests or tracking customer complaints

- Difficulties trending warranty claims and vendor issues

- Lack of visibility into compliance and training documentation

“I remembered how much Frontline helped at my previous company. I knew it could do the same here,” explained Lynn Benishek, Director of Operations at Optec LED Lighting.

Why Frontline: Flexibility Without the Complexity

Lynn evaluated other quality management system (QMS) tools but found them overly complex and cost-prohibitive for a lean team. What stood out about Frontline was its flexibility, affordability, and ability to scale without needing IT involvement.

“I showed the engineering team some demos,” Lynn said. “They were impressed. And the price point made it a no-brainer.”

Even though Frontline is often marketed as an EHS solution, Lynn saw its potential for quality, training, operations, and ISO prep. With the support of Frontline’s customer success team, the implementation journey began.

Implementation: Building the System from Scratch

Since Optec LED Lighting was essentially a start-up operation, Lynn and her team didn’t need to port over legacy systems. Instead, they built workflows from scratch—an opportunity and a challenge.

“Honestly, creating the processes was the hard part. But setting them up in Frontline? That part was smooth.”

Frontline’s support team, especially Alyssa, helped translate Word and Excel documents into dynamic, trackable workflows. The software training was hands-on and paced for real-world use. And since no IT team was available, Lynn appreciated how easily she could administer the system herself.

Results: Operational Excellence for Optec LED Lighting

After implementing Frontline, Optec LED Lighting saw measurable improvements:

1. Workflow Visibility and Task Ownership

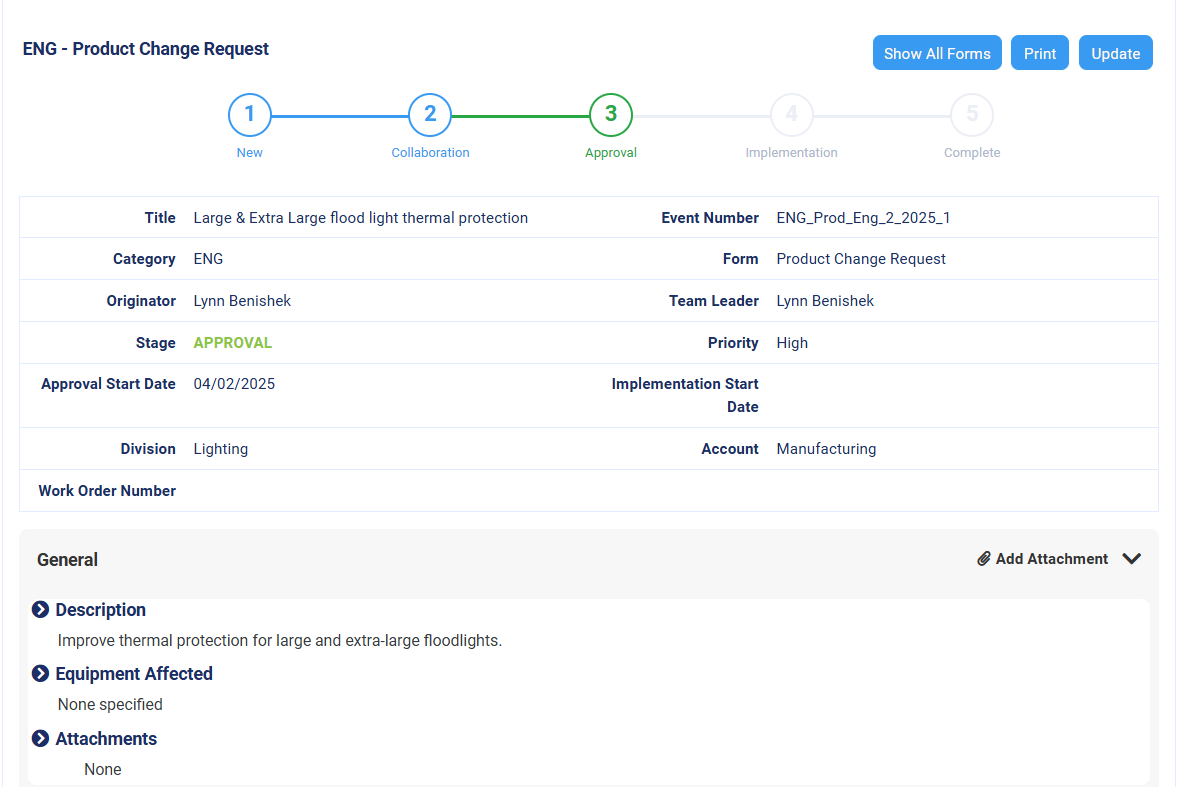

Before Frontline, tasks were assigned verbally or by email—often lost in the shuffle. Now, with Frontline’s Events and Actions, every request is visible, accountable, and trackable.

“No more ‘I thought you were doing it!’” Lynn laughed. “Everyone knows what’s on their plate. And if someone gets stuck, they can easily reassign or collaborate.”

2. Supplier Rejection Reporting

One of the most impactful uses of Frontline has been supplier accountability. Using Frontline’s smart forms and reporting, Lynn was able to create professional-grade reports documenting vendor issues.

“I used to send patchy Excel files. Now, I send detailed, numbered reports that clearly outline what went wrong. It looks polished and holds vendors accountable.”

3. Customer Complaint Management

Optec LED Lighting now handles warranty claims and customer complaints with structure and speed. Events in Frontline ACT capture the complaint, while Actions drive resolution, whether that’s repair, replacement, or a corrective engineering change.

“Everything’s tied together: the complaint, the fix, the corrective action. Nothing gets lost.”

4. Training and Knowledge Transfer

Training modules in Frontline ensure that every stakeholder is not only informed but accountable. New team members can instantly access past complaints, fixes, and reasons behind engineering decisions.

“We had an engineer leave with years of organizational product knowledge. Now, with Frontline, we can document everything. Anyone new can run a report and get the full story of changes or history of a product.”

5. Safety Compliance and Audits

Optec LED Lighting used Frontline to formalize their safety program. Now, they use Frontline to track activities such as forklift start-up checklists, safety audits, preventive maintenance and calibration, electrical safety training, and other safety program requirements.

“Our team members log everything—from daily checks to monthly audits. Because recurring tasks are assigned automatically, team members never forget.”

Key Features Driving Value

Optec LED Lighting uses a wide range of Frontline ACT tools, including:

- Events: To log issues, changes, and complaints

- Actions: To assign, track, and verify completion

- Training: To confirm knowledge and enable process reinforcement

- Smart Forms: To customize workflows and collect structured data

- Reporting: To generate vendor-facing documentation and internal audits

Frontline serves as both a QMS and an operational hub, making it a “one-stop shop” for a lean manufacturing team.

Quantifiable and Anecdotal ROI

While exact metrics vary by use case, the return on investment has been clear:

- Faster complaint resolution

- Reduced administrative overhead

- Avoided headcount growth

- Improved vendor performance

- More successful audits and customer confidence

“Honestly, we wouldn’t be able to keep our team this small without Frontline. It’s a force multiplier.”

Support That Feels Like an Extension of the Team

Customer support has been a highlight of the Frontline experience. Even as new features like smart forms roll out, Frontline provides training without extra cost or delays.

“Alyssa checks in every quarter. If I need something, she’s on it right away. During implementation, she even built forms for us. That level of help? You just don’t see it often.”

Lessons Learned: Build It Right the First Time

For other manufacturers evaluating QMS or EHS software, Lynn offers this advice:

- Start early: Don’t wait for chaos to make you act.

- Keep it simple: Build workflows around real daily needs.

- Use your resources: Frontline’s team is there to help.

- Document everything: You’ll thank yourself when staff turnover.

- And most importantly: You don’t need a full-time IT team. You just need the right tool.

- Final Word: Frontline is more than an EHS software. It’s a low-cost, high-impact platform that grows with your team and comes with a partnership you can count on.

While Frontline is often positioned as an EHS solution, Lynn’s story proves it’s much more. For small-to-midsize manufacturers, it’s a versatile platform for quality, operations, and audit readiness.

“I’d recommend Frontline to anyone. It’s flexible, cost-effective, and scales with you. And the best part? It works—without the IT headaches.”

Are you a lean manufacturing team looking to streamline workflows, prep for audits, and centralize operations—without the need for IT? Book a demo with Frontline and see how it can transform your quality and compliance systems like it did for Optec LED Lighting.

Put Down the Pen and Switch to Frontline ACT

From the day you implement our software system, you’ll be able to manage important components of your EHS program and track your team’s progress.