CASE STUDY

How NCTI Strengthened Process Safety with Frontline MOC

Using Frontline MOC, Nippon Chemical Texas Incorporated (NCTI) transformed process safety by creating a robust system for compliance, operational visibility, and safety culture.

Meet NCTI

Nippon Chemical Texas Incorporated is a leader in the chemical industry, known for pioneering the global market on new chemical formulations. Over the years, NCTI has expanded its operations, creating the need for a more reliable and scalable solution for managing process safety.

Industry: Chemical Manufacturing

Company Size: 100+ employees

Challenges: Enhancing process safety compliance and reducing downtime

Solutions: Frontline MOC, Frontline ACT, Frontline LMS

The Challenge: Inadequate Tools for a Growing Operation

One of the challenges of growth in a high-risk industry is maintaining safety across locations. This is exactly what NCTI experienced as they began expanding operations. The more the company grew, the more limitations they faced with their existing process safety management (PSM) systems.

Their systems lacked the control measures needed to handle compliance across multiple sites. In fact, one system allowed for a single user to initiate and complete a change with only one approval. In terms of regulatory oversight, this was a serious shortfall.

Also, the software was prone to frequent crashes, creating unacceptable periods of downtime. As the facility grew in scale and complexity, these weaknesses increased the risk of implementing changes without meeting all compliance requirements. As a leader in the chemical manufacturing field, NCTI saw the critical need to ensure compliance at every step, so they went in search of a better solution.

The Solution: Frontline MOC Drives Compliance and Collaboration

NCTI turned to Frontline Data Solutions to overhaul its management of change program. They adopted the Frontline MOC software solution to introduce a standard process across the entire operation.

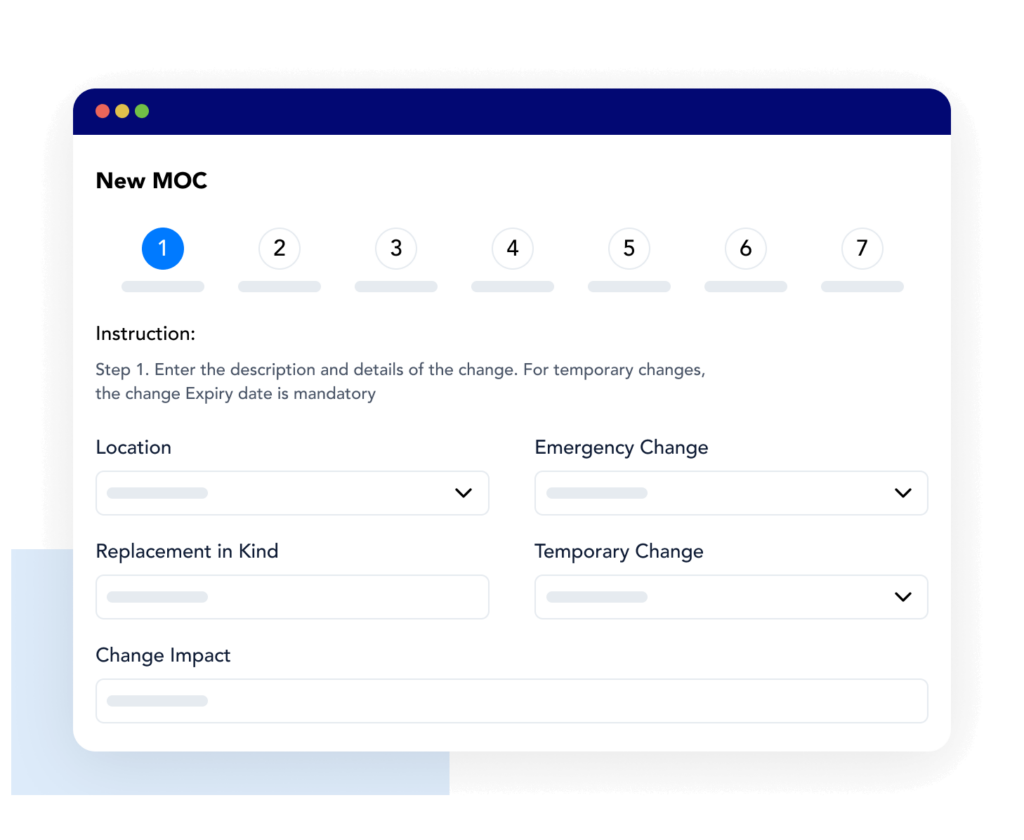

Unlike their previous systems, Frontline MOC had a multi-layered approval workflow that immediately addressed a major compliance gap:

It ensured that changes could no longer be completed without multiple, cross-disciplinary approvals.

This built-in requirement for involvement from various departments helped verify that NCTI’s team followed all regulatory steps before making any changes. Because of Frontline MOC’s applicability to PSM compliance and other types of change management, NCTI improved multiple processes at once.

They liked that Frontline MOC:

- Forced involvement from multiple departments to complete a change

- Allowed for mass assignment of learners (to expedite assignments)

- Provided electronic notifications to all affected employees

- Made documentation of notifications quick and easy

- Enabled multidisciplinary reviews during the design safety review (DSR)

- Permitted role-based assignments for more efficient task delegation

Frontline also supported broader safety efforts through its computer-based training (CBT) library and post-incident review features, increasing safety awareness across the facility.

The Results: Improved Safety, Faster Processes, and Stronger Compliance at NCTI

Since implementing Frontline MOC, NCTI has seen a marked improvement in its safety culture and compliance posture. One of the reasons why they’ve been so successful with incident prevention is because Frontline MOC allows them to “identify potential issues before they escalate into significant problems.”

At its core, change management is a proactive strategy which, in NCTI’s case, positively strengthened their team’s safety culture. That’s because the process of carefully planning, reviewing, and implementing potentially hazardous changes allows the team to eliminate as much risk as possible beforehand.

Beyond safety metrics, NCTI has also experienced significant operational benefits since adopting Frontline MOC:

- Reduced downtime and quicker project completions thanks to a centralized, efficient workflow

- Better visibility into potential issues, enabling a more proactive and cost-effective safety strategy

- Prevention of noncompliance fines, with audit-ready documentation and regulatory alignment

Importantly, the platform is user-friendly even for employees who only occasionally interact with it. In a market full of complex software systems, having a simple approach within Frontline MOC saves time and reduces training burdens.

A Reliable Partner for the Long Haul

One standout benefit of partnering with Frontline Data Solutions is their reliability as an EHS software provider. Unlike past solutions, Frontline MOC “consistently performs well without significant downtime,” which is crucial for maintaining operational efficiency.

Customer support at Frontline Data Solutions has been another standout for NCTI. Over three years, the company has collaborated closely with Frontline’s team to refine its system and adjust workflows, most recently enhancing its incident management process.

NCTI strongly recommends Frontline Data Solutions to other chemical manufacturers looking to modernize and strengthen their EHS practices. As Dennis Cranfill, EHS Manager at NCTI puts it:

“Their focus on simplifying complex processes while ensuring compliance with safety regulations, along with excellent customer service, makes them a valuable partner in enhancing workplace safety.”

– Dennis Cranfill, EHS Manager at NCTI

Are you a chemical manufacturing team looking to improve your management of change processes, improve compliance, and boost efficiency? Book a demo and see how Frontline MOC can do all of this and more like it did for Nippon Chemical Texas Incorporated.

Take Back Control of Your MOC Process

From the day you implement Frontline MOC, you’ll get better visibility over operational changes, better compliance documentation, and better reporting.